Blog

-

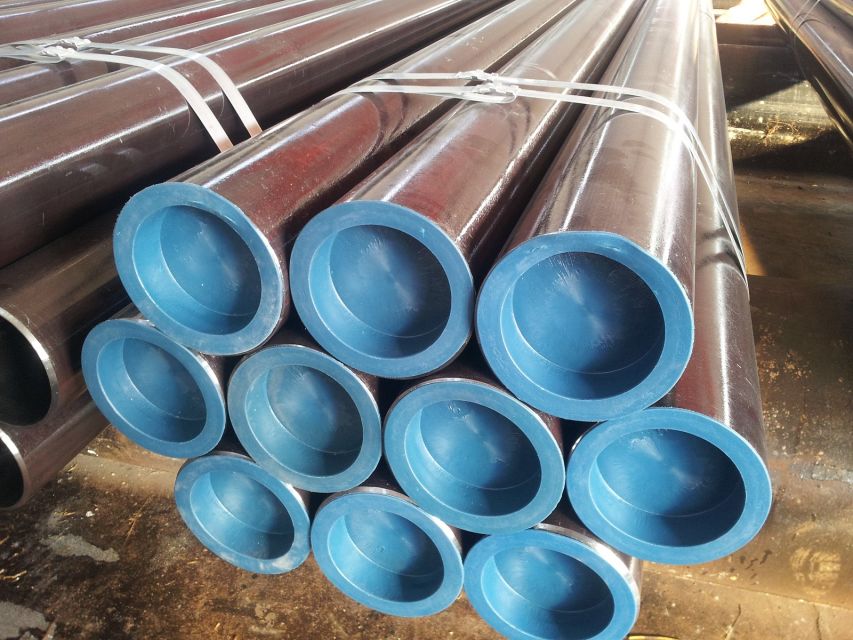

ERW Steel Pipe -304 stainless steel pipes tube

Are you looking for hot selling stainless steel bars coil 304 stainless steel pipes tubing? Here, you can also find 310 316l stainless steel pipes tubing. Know more, welcome to contact us, we look foward to being your partener.If you’re in need of a corrosion-resistant, durable, and easy-to-install option for your commercial or industrial applications, our Hot Selling 304 Stainless Steel Pipes Tubing is the perfect solution. It’s ideal for plumbing, food processing, and chemical plants, and the stainless steel bars are strong and reliable. The tubing is also flexible and can be cut to any size you need. Don’t hesitate to experience the quality and reliability of our stainless steel pipes and tubing for yourself!Read more -

ERW Steel Pipe -Steel Grades You Might Buy in China

When selecting the right metal for your job, there are several factors that you need to consider:Hardness– capacity to resist abrasion, but also difficulty in being cut or drilledStrength– the amount of force necessary to deform the metalToughness– ability to resist stress (and not break)Malleability – the ability of the metal to deformWeldability– ability to be welded (it’s a function of melting point, heat conductivity, etc.)Download a thorough spreadsheet which explains the popular steel grades in detail here.Read more -

How do you bend stainless steel tubing with heat?-ERW and EFW Steel Pipe

If you're looking to create a stainless steel tubing coil, one of the most important steps is bending the tubing to the desired shape. Bending stainless steel tubing can be a tricky process, but with the right tools and techniques, it's possible to create the perfect coil every time.Read more -

Stainless Steel EFW Pipe-Guide to Steel Tube and Aluminum Tube Bending

Aluminum Tube bending is a common forming process that we as metal manufacturers practice. Additionally, it happens to be the main operation when it comes to tubing and piping. There are, however, a few factors to consider before carrying out tube bending. Here is an outline of what we are going to cover.Read more -

Welded Steel Pipe-How to Bend Stainless Steel Tubing: Basics, Methods, 90° Bending

Bending stainless steel tubing can be achieved through manual, heat, mechanical, mandrel, or induction methods. Manual bending involves tube benders to manually bend the tubing, while heat bending makes stainless steel more pliable using torches or heat guns. Mechanical bending employs machinery like CNC tube benders for precise bends. Mandrel bending uses rods inserted inside the tube to prevent collapse. Induction bending locally heats the tubing with induction heating for shaping. Each method requires careful consideration of factors like tubing diameter, wall thickness, and bend radius to avoid compromising the tubing’s integrity. Proper tools and techniques are crucial to prevent damage during the bending process.Read more -

Stainless Steel Tube Bending: Process & Considerations

Stainless steel is one of the most popular materials used for custom tube bending due to its excellent strength and superior resistance to corrosion. It is the ideal choice for a variety tube and pipe components, including OEM instruments and machinery, manifolds and hydraulic fluid supply lines, cooling coils, water nozzles, and more.Read more -

SAW vs ERW and EFW Welded Steel Pipe-How to Bend Steel Pipe- A Complete Guide

Steel pipe is an incredibly versatile material, and it’s no wonder that it’s a popular choice for use in many different projects. But how do you bend steel pipe? It’s not as difficult as it might seem! With the right tools and a little bit of know-how, you can master the art of bending steel pipe in no time.Read more -

Stainless steel-HOW TO CLEAN AND CARE FOR STAINLESS STEEL SURFACES

Wash the exterior surfaces and gaskets with warm water and mild soap or detergent. Wipe and dry. We recommend using a clean micro fiber cloth or a soft clean cloth to polish and dry. Ensure to thoroughly dry all surfaces. IMPORTANT: To avoid damage to the finish, do not use soap-filled scouring pads, abrasive or harsh cleaners, any cleaning product containing chlorine bleach, steel-wool pads, gritty wash cloths or paper towels. Using these types of products may scratch and/or dull the clear coat of the black stainless steel door.Read more -

Stainless steel-How To Clean Stainless Steel Appliances Like a Pro

Learn to maintain the shine and prevent scratches with our guide on how to clean stainless steel appliances like a pro. Stainless steel appliances can add a stylish touch to your home, with their pristine shine and modern look. After a few months, even stainless steel can start to lose its shine and smudge-free appearance. We’ve uncovered the tried and true methods to clean your appliances that will make them sparkle again. Here’s everything you need to know about how to properly clean stainless steel appliances and remove those pesky streaks for good.Read more