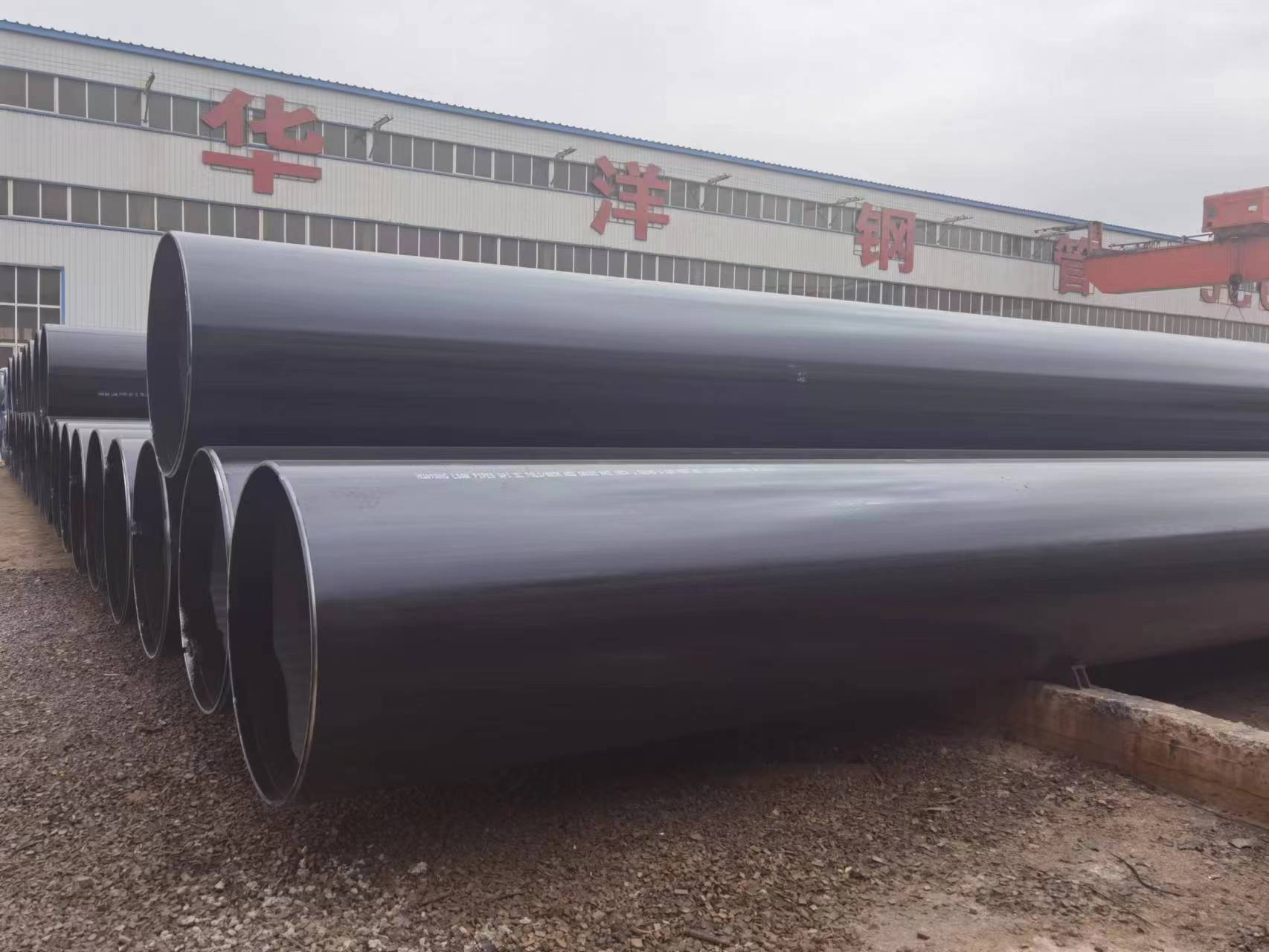

Our EFW steel pipe covers steel pipe 16 inches in outside diameter or larger that is electric fusion welded (EFW) with filler metal added, fabricated from pressure vessel quality plate . Several grades designate the type of plate used; classes designate the type of heat treatment performed during the manufacture of the pipe, whether the weld is radiographically examined, and if the pipe has been pressure tested.

EFW Pipe Specification

- OD:16”-56”

Wallthickness:8mm-45mm

Length:5.8m-14m

Standard: ASTM A672 ASTM A671

ASTM A672 Standard Specification for Electric-Fusion-Welded Steel Pipe for High-Pressure Service at Moderate Temperatures

Carbon Steel ASTM A671 EFW Straight Welded pipe is designed to be used in those applications, where the temperature ranges between ambience to low temperatures. This carbon steel specified ASTM A671 Pipe has been fabricated from a plate that is of a pressure vessel quality. A reason why our clients prefer using this carbon based steel A671 Welded pipe is due to its low cost in comparison to other stainless steel grade.

Chemical composition

Product analysis of plate: The pipe manufacturer shall make an analysis of each mill heat of plate material. The product analysis shall meet the requirements of the plate specification to which the material was ordered.

Product analysis of weld: The erw pipe supplier shall make an analysis of the finished deposited weld material from each 500 feet or fraction thereof. Analysis shall conform to the welding procedure for deposited weld metal.

Heat treatment

Classes 10, 11, 12 and 13 are not heat treated. All other classes must be heat treated according to the parameters as Standard Permissible Variations in Wall Thickness and Weight

Dictated by the requirements of the specification to which the efw pipe manufacturer ordered the plate. Permissible Variations in Outside Diameter

Based on circumferential measurement +/-0.5% of the specified outside diameter.

ERW Pipe FAQs

What Is Efw Pipe?

EFW (Electric Fusion Welded) pipe is a type of steel pipe manufactured using the electric fusion welding process, where the material is melted and fused together. It is known for its strength, corrosion resistance, and suitability for high-pressure applications. EFW pipes are commonly used in various industries, including petrochemical, oil and gas, and power generation.

What materials are commonly used in the production of EFW pipes?

EFW pipes are typically made from materials such as stainless steel, carbon steel, and various alloy steels, depending on the specific application requirements.

What are the advantages of using EFW pipes?

EFW pipes offer excellent strength, corrosion resistance, and the ability to withstand high temperatures and pressures. The fusion welding process ensures a strong and durable bond between materials.

What sizes are available for EFW pipes?

EFW pipes come in a wide range of sizes, from small diameters used in plumbing to large diameters for industrial and infrastructure projects.

EFW pipe vs SSAW pipe,ERW pipe

EFW Pipe:

Process: Manufactured using electric fusion welding, involving the melting and fusion of materials.

Advantages: Strong, corrosion-resistant, suitable for high-pressure applications.

Applications: Commonly used in petrochemical, oil and gas, and power generation industries.

SSAW Pipe (Submerged Arc Welded):

Process: Welding is done by submerged arc welding process, forming a spiral shape.

Advantages: Suitable for long-distance pipelines, high strength, and uniformity.

Applications: Used in oil and gas transmission pipelines, piling, and structural applications.

ERW Pipe (Electric Resistance Welded):

Process: Manufactured by rolling metal and then welding along the seam using electric resistance.

Advantages: High efficiency, cost-effective, suitable for small to medium diameters.

Applications: Commonly used in construction, plumbing, and various industrial applications.

Comparison:

Welding Process: EFW and ERW use electric welding, while SSAW involves submerged arc welding in a spiral formation.

Strength: EFW and SSAW pipes are known for their strength, suitable for high-pressure applications, while ERW pipes are efficient for lower to medium pressure uses.

Applications: EFW and ERW are versatile and used in various industries, whereas SSAW is often preferred for long-distance pipelines due to its spiral construction.