Introduction

Our Metal Welding Services are one of the most reliable and versatile products available in the market today. Perfect for industrial, commercial and even personal use, our welding services provide a broad array of advantages that make them a must-have for any business.

As a manufacturer located in China, our Metal Welding Services are designed to meet the highest standards in quality and workmanship, making them an ideal choice for merchants looking for high-quality, durable, and cost-effective welding services.

So whether you're searching for a reliable and efficient welding service for your construction projects, automotive repair shops or custom fabrication work, our Metal Welding Services are the perfect solution.

Here are some of the features and benefits of our Metal Welding Services that set us apart from our competitors.

Reliability

Our Metal Welding Services are built to last. With a focus on quality materials and workmanship, we ensure that our products are robust and reliable.

We employ skilled professionals who are experts in welding technology and can provide you with the necessary expertise to deliver an excellent product. We utilize precision machines and tools to manufacture some of the highest quality and flawless welding services in the market.

Durability

Our Metal Welding Services are highly durable, making them ideal for industrial and commercial use. We use top-quality materials, including steel and aluminum, to produce products that do not rust, corrode, or wear down quickly.

Our welding services are built to withstand a high level of pressure, impact, and wear and tear, so they last longer and require minimal repairs and maintenance.

Cost-effective

Our Metal Welding Services are highly cost-effective. We understand that businesses need to operate efficiently and economically, so we strive to offer the best value for our products.

Our welding services are competitively priced, so you can get a top-quality product at an affordable price. Additionally, our services require minimal maintenance, making them a cost-effective investment.

Customization

We provide customization on our Metal Welding Services, making it possible to meet your specific requirements. Our skilled professionals can help you design and produce customized products that meet your unique needs.

Whether you need a specific metal and welding technique, a particular size, shape, or finish, we have got you covered. With our custom welding services, you can get a product that exactly meets your requirements.

Technology

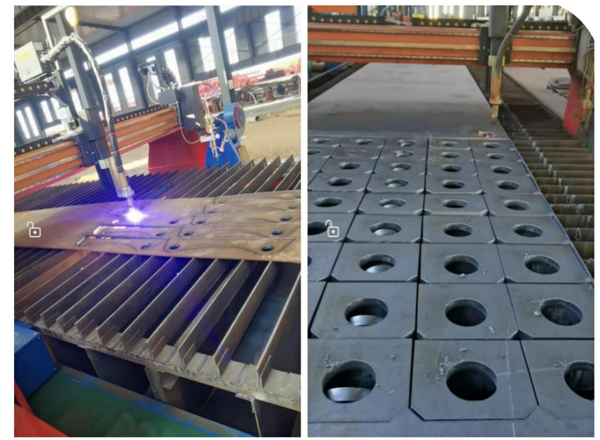

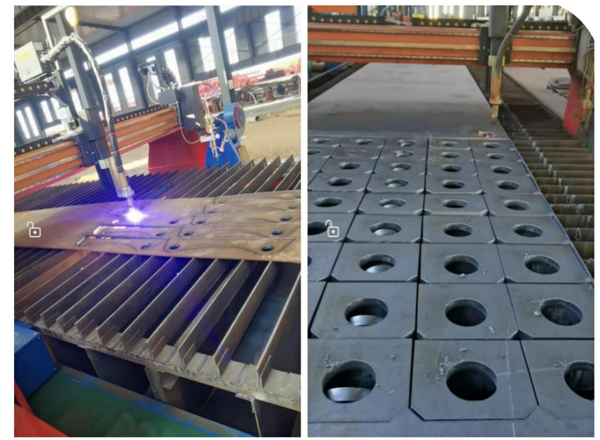

Our metal welding techniques employ the latest technology and machinery to produce high-quality results. We have invested in top-of-the-line equipment such as laser welding machines, die-cutting machines, CNC milling, plasma cutting, among others. We keep updating and upgrading our machinery and welding techniques to stay at the forefront of the industry.

Our welding services use cutting-edge computer technology that ensures precision and accuracy from concept to finished product. Our professionals use advanced CAD and CAM software to design, engineer, and manufacture products that meet your exact requirements.

Quality Assurance

We understand that a sub-standard product can have far-reaching effects on your business's reputation and performance. To that end, we have implemented a quality control system to ensure that all our products meet the highest quality standards.

Our quality control system checks for performance, accuracy, dimension, and finish, among other factors. We conduct regular checks on our production processes to identify and rectify any issues with the quality of our products.

Conclusion

Our Metal Welding Services offer unmatched reliability, durability, cost-effectiveness, customization, and advanced technological features that make them one of the best in the market. They are ideal for construction, automotive, and custom fabrication work, and they can be customized to meet your specific needs.

At our manufacturing facility in China, we have skilled professionals, up-to-date machinery, and a quality control system in place to ensure that our products meet the highest quality standards.

Whether you're looking for a quality welding service provider for your business or personal projects, you can count on our Metal Welding Services to deliver excellent results, guaranteed to meet or exceed your expectations.

Steel pipe special welding processing service-Welding prefabrication work

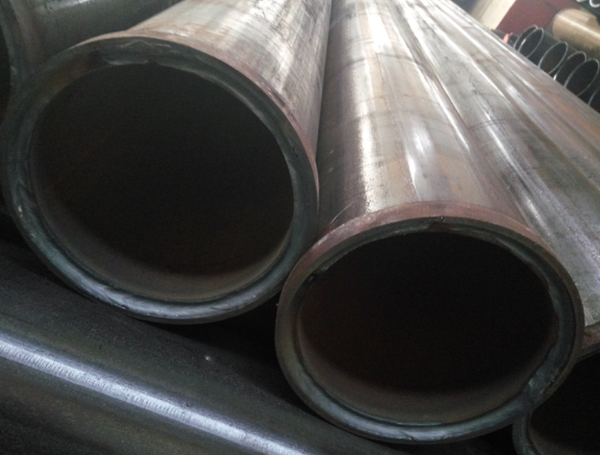

Except the steel pipe manufacturer, huayang steel pipe could supply the special welding processing service to meet the different requirement of customers(Welding prefabrication work ) as below:

Welding prefabrication work between pipe and steel refers to the process of joining two or more pieces of metal, specifically pipes and steel structures, through welding prior to their installation on the job site. This process is often used in the construction industry as a means of improving productivity, quality, and safety by performing welding work offsite.

Prefabrication welding involves preparing and welding the components in a controlled environment such as a workshop or factory, rather than in the field. This is done to avoid weather-related delays, minimize the risk of accidents, and ensure consistent quality of the welds. The prefabricated components are then transported to the job site where they are assembled to create the final product.

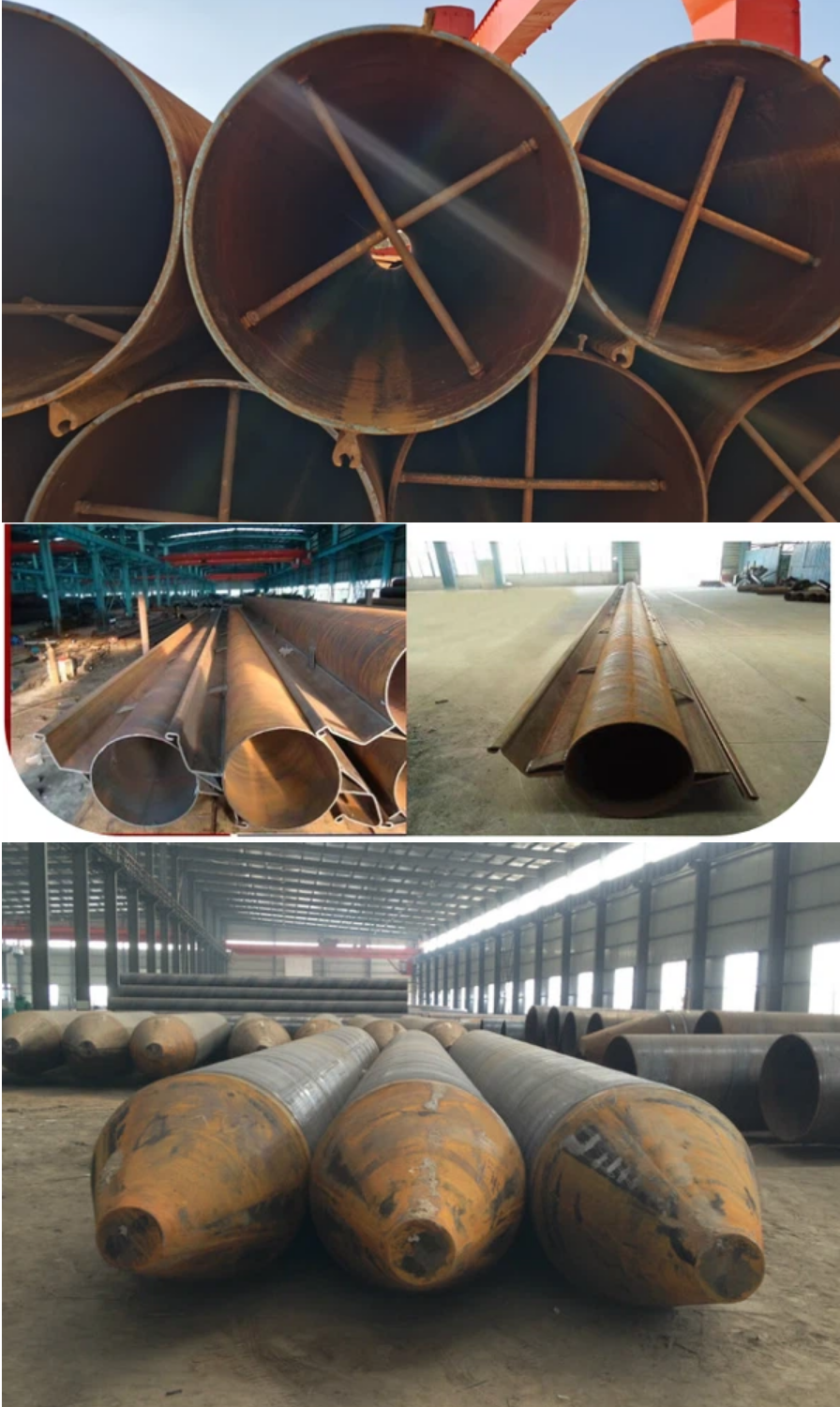

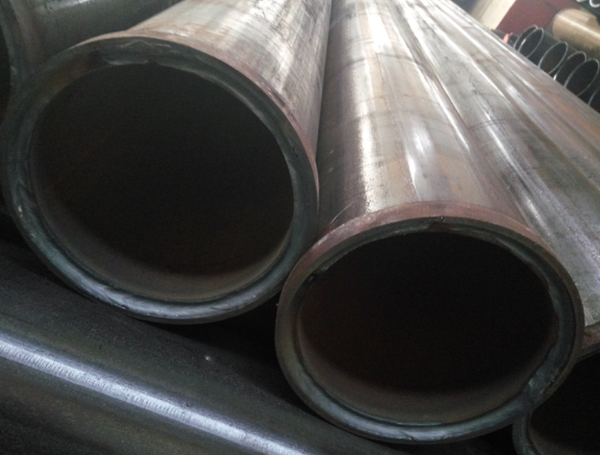

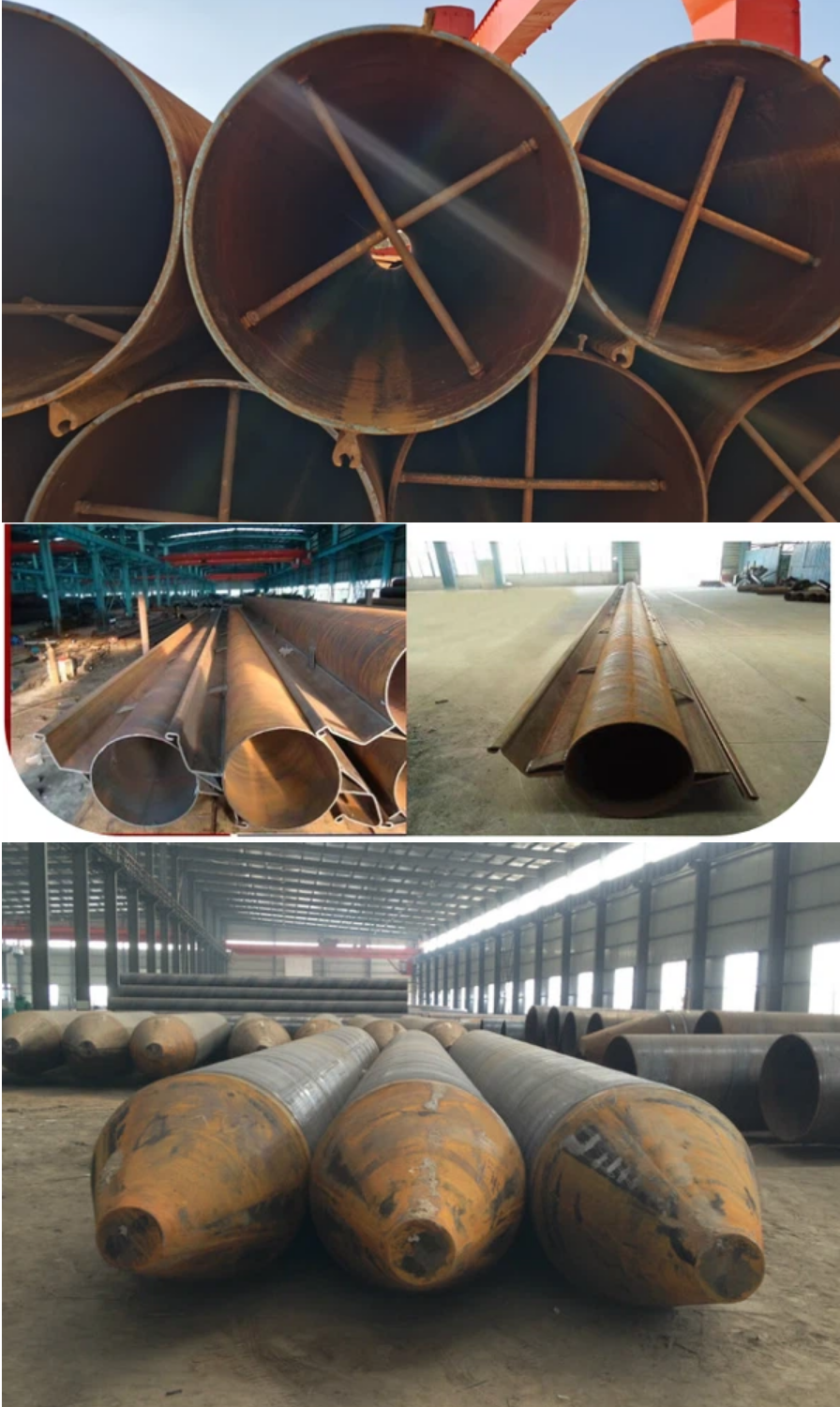

1.Steel pipe butt welding

The maximum diameter up to 3 meters and the maximum length up to 36 meters

2.pipe and flange welding

For pipe connection

3. pipe support

Steel bracing always used for subway construction

4. Interlocking pipe piles

5. Pipe weld stud

For city construction, main beam of the construction

6. Steel plate cutting -Cutting & Beveling

7. Traffic sign pole

8. Lattice steel column

9. Steel pipe nesting and reinforcement

10. Pile poles

Generally refers to the tip of the prestressed pipe pile. It is used for the foundation construction of the prestressed concrete pipe pile and the front end of the pipe pile. It is installed on the pipe pile to guide and block the pipe pile when the pipe pile sinks

11. Shoulder pipe -Pipe end weld Shoulder ring

In summary, welding prefabrication work between pipe and steel is a process of joining metal components prior to installation on the job site, with the goal of improving productivity, quality, and safety.

If you need, please contact us, Huayang Steel pipe will do our best to serve you