7 月 . 31, 2024 23:48 Back to list

Wholesale Suppliers of ERW Steel Pipes Complying with ASTM A53A Standards and Specifications

Understanding Wholesale ERW Steel Pipes A Focus on ASTM A53A Factories

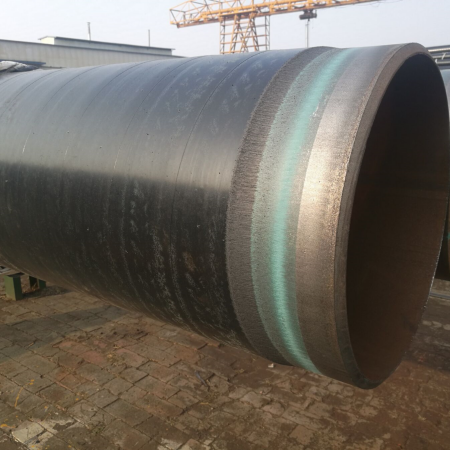

In the world of construction and industrial applications, the importance of high-quality steel pipes cannot be overstated. Among the various types of steel pipes available, Electric Resistance Welded (ERW) steel pipes are particularly notable for their strength, durability, and cost-effectiveness. These pipes are widely used in various applications, including water and gas distribution, plumbing, and structural components. This article focuses on wholesale ERW steel pipes, particularly those meeting the ASTM A53A specification, and the factories that manufacture them.

What are ERW Steel Pipes?

ERW steel pipes are produced by rolling steel and welding it longitudinally. This process utilizes a high-frequency electric current to heat the edges of the steel strips, which are then pressed together to form a weld. This method not only speeds up production but also provides a strong bond, making ERW pipes suitable for high-pressure applications.

The ASTM A53A specification is one of the standard specifications set by the American Society for Testing and Materials (ASTM). It covers seamless and welded black and hot-dipped galvanized steel pipe intended for mechanical and pressure applications. These pipes are crucial in many industries, as they meet rigorous safety and quality standards.

The Importance of Factories in Producing ASTM A53A ERW Pipes

Manufacturers play a significant role in ensuring the quality and availability of ERW steel pipes. Factories that specialize in producing ASTM A53A pipes use advanced technology and stringent quality control measures to guarantee that their products meet industry standards. These factories invest in state-of-the-art equipment to execute precise manufacturing processes.

Moreover, the sourcing of raw materials is essential. High-grade steel is sourced to ensure that the final product is both strong and reliable. The manufacturing process also involves rigorous testing at various stages, including non-destructive testing, to identify any defects earlier on. This level of scrutiny is crucial for meeting the requirements of industries such as oil and gas, construction, and utilities.

The Wholesale Market for ERW Steel Pipes

wholesale erw steel pipe astm a53a factories

The wholesale market for ERW steel pipes is booming, fueled by the growing demand for infrastructure development and construction projects worldwide

. Wholesale suppliers focus on bulk quantities, which not only lower costs but also provide an efficient solution for contractors and businesses needing large volumes of steel pipes.When choosing a wholesale supplier for ASTM A53A ERW steel pipes, several factors should be considered

1. Quality Assurance Look for suppliers who guarantee that their products meet ASTM specifications and who conduct regular quality checks during production.

2. Certifications Ensure that the factories are certified and adhere to international quality management standards, such as ISO 9001.

3. Customization Many projects require specific dimensions and coatings. A good supplier should offer customization options to meet project needs.

4. Customer Support Reliable customer service is essential for addressing inquiries, concerns, or concerns during the procurement process.

5. Delivery Capability The ability to meet delivery schedules is critical in construction projects. Suppliers should have a robust logistics network to ensure timely delivery.

Conclusion

Buying wholesale ERW steel pipes, particularly those that conform to the ASTM A53A standard, is a strategic decision for businesses in construction, energy, and manufacturing. By selecting reputable factories that prioritize quality, compliance, and customer satisfaction, contractors can ensure that they obtain robust materials capable of withstanding the demands of modern applications. As the construction industry continues to grow, the role of high-quality steel pipes will remain paramount in supporting various infrastructures worldwide.

-

High Quality Mild Steel Pipe Manufacturers in China for Exporting Premium Industrial Solutions

NewsAug.01,2024

-

Exploring Key Characteristics of Wholesale API Steel Pipes for Your Business Needs

NewsAug.01,2024

-

Current Wholesale Prices for ERW Steel Pipes in the Market Right Now

NewsAug.01,2024

-

Exploring the Diverse Applications and Benefits of China Round Steel Pipes in Construction and Industry

NewsAug.01,2024

-

Top Quality API 5L ERW Steel Pipe Manufacturer Offering Reliable and Durable Solutions for Your Needs

NewsAug.01,2024

-

Reliable Supplier of Premium Quality Concrete Pipes for Durable Construction Projects

NewsAug.01,2024