7 月 . 26, 2024 00:42 Back to list

Top Manufacturers of High-Quality 3LPE Pipes for Reliable Industrial Applications and Projects

High-Quality 3LPE Pipe Manufacturers Ensuring Durability and Reliability

In the realm of piping solutions, the demand for durable and reliable materials is ever-increasing. Among the various options available, 3LPE (Three-Layer Polyethylene) pipes have emerged as a preferred choice for many industries. These pipes are constructed using a three-layer coating process that includes a fusion-bonded epoxy layer, a polyethylene adhesive layer, and an outer layer of polyethylene. This unique construction provides a host of advantages, making it essential to source them from high-quality manufacturers.

The Importance of Quality in 3LPE Pipe Manufacturing

When it comes to pipeline systems used in oil and gas, water supply, and other critical applications, the quality of materials cannot be compromised. High-quality 3LPE pipes exhibit remarkable resistance to corrosion, which is a significant factor for outdoor and underground installations. These pipes protect the steel substrate against external and internal corrosion, ensuring longevity and reducing maintenance costs over time.

High-quality manufacturers utilize advanced technologies and adhere to international standards during the production process. This diligence results in pipes that not only meet but often exceed industry specifications, thus offering enhanced performance. Additionally, these manufacturers conduct rigorous quality control tests to ensure that each batch performs reliably under various conditions.

Key Features of 3LPE Pipes from Reputable Manufacturers

1. Corrosion Resistance The primary feature of 3LPE pipes is their exceptional resistance to corrosion. The fusion-bonded epoxy coating acts as a barrier against water and other corrosive agents, thus extending the lifespan of the pipeline.

2. Mechanical Protection The outer polyethylene layer provides additional mechanical protection, making the pipes robust against physical damage. This is particularly important during transportation and installation.

3. Temperature Stability High-quality 3LPE pipes can withstand a wide range of temperatures. This stability ensures that they perform effectively in various environmental conditions, making them suitable for both hot and cold water applications.

4. Environmentally Friendly Some reputable manufacturers focus on sustainability by using recyclable materials for their 3LPE pipes. This commitment to the environment not only helps in reducing waste but also appeals to eco-conscious clients.

high quality 3lpe pipe manufacturers

5. Custom Solutions Leading manufacturers often offer custom solutions to meet specific project requirements. This flexibility allows clients to choose pipe dimensions, thickness, and coating types that align with their operational needs.

Choosing the Right Manufacturer

When searching for high-quality 3LPE pipe manufacturers, it’s crucial to consider several factors

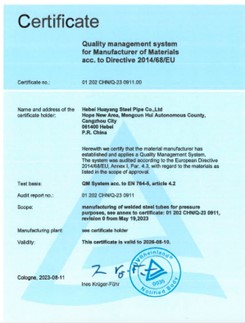

- Certification and Compliance Look for manufacturers that are certified to international quality standards such as ISO 9001. Compliance with industry standards assures that the products have been thoroughly tested for safety and reliability.

- Experience and Reputation Research the manufacturer’s history and reputation in the industry. Established companies with a proven track record are more likely to deliver trustworthy products.

- Customer Support Good customer support is essential. Manufacturers that offer technical support and after-sales service can help address any issues that may arise during installation or operation.

- Reviews and Testimonials Customer reviews and testimonials provide insight into the quality of products and services offered by the manufacturer. Positive feedback can indicate reliability and satisfaction among clients.

Conclusion

Investing in high-quality 3LPE pipes is critical for ensuring the robust performance of pipeline systems. By choosing reputable manufacturers, businesses can secure products that offer enhanced durability, corrosion resistance, and overall reliability. In an industry where safety and efficiency are paramount, the importance of selecting the right materials cannot be overstated. As the demand for sustainable and reliable infrastructure continues to grow, so too will the importance of high-quality 3LPE pipe manufacturers in supporting these initiatives.

-

High Quality Mild Steel Pipe Manufacturers in China for Exporting Premium Industrial Solutions

NewsAug.01,2024

-

Exploring Key Characteristics of Wholesale API Steel Pipes for Your Business Needs

NewsAug.01,2024

-

Current Wholesale Prices for ERW Steel Pipes in the Market Right Now

NewsAug.01,2024

-

Exploring the Diverse Applications and Benefits of China Round Steel Pipes in Construction and Industry

NewsAug.01,2024

-

Top Quality API 5L ERW Steel Pipe Manufacturer Offering Reliable and Durable Solutions for Your Needs

NewsAug.01,2024

-

Reliable Supplier of Premium Quality Concrete Pipes for Durable Construction Projects

NewsAug.01,2024