7 月 . 27, 2024 07:07 Back to list

Top Exporters of High Quality ERW A53 Steel Pipes for Industrial Applications

The Significance of High-Quality 12 Steel Pipe STD ERW A53 in Global Exports

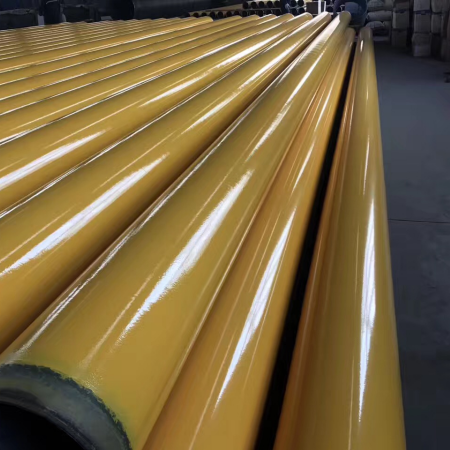

In the realm of construction and manufacturing, the demand for high-quality steel pipes has steadily increased, with specific attention to ERW (Electric Resistance Welded) pipes. Among the various standards available, the ASTM A53 specification stands out, particularly the high-quality 12 steel pipe variant. This article delves into the significance of A53 ERW steel pipes in the global market, focusing on their quality, applications, and the role of exporters in enhancing their availability and use.

Understanding ASTM A53 Standard

ASTM A53 is a specification that covers seamless and welded steel pipes

. ERW A53 pipes are specifically designed for use in mechanical and pressure applications, making them ideal for various structural and industrial uses. The designation “12” typically refers to the pipe's nominal diameter, an essential factor in engineering and construction.High-quality A53 ERW pipes are manufactured using controlled practices to ensure consistent quality and reliability. These pipes are known for their superior tensile strength, excellent corrosion resistance, and suitability for high-pressure environments. Industries such as oil and gas, water supply, and construction heavily rely on these pipes for both load-bearing and transmission applications.

Importance of Quality

The importance of high-quality steel pipes cannot be overstated. In an industry where safety and structural integrity are paramount, A53 ERW pipes offer the assurance that they will perform under rigorous conditions. High-quality steel pipes help prevent leaks, reduce maintenance costs, and enhance the overall lifespan of installations. Moreover, the adherence to rigorous international standards ensures that products meet specific performance requirements, thereby providing end-users with confidence in their reliability.

Applications of A53 ERW Steel Pipes

high quality 12 steel pipe std erw a53 exporters

A53 ERW steel pipes are versatile and find applications across various sectors. In construction, they are used for structural purposes, such as support beams and frameworks. In the oil and gas sector, they serve as conduits for the transportation of fluids, gases, and other materials. Furthermore, they are employed in the manufacturing of scaffolding, ensuring stability and safety on construction sites.

The adaptability of A53 ERW pipes also extends to residential plumbing systems, where their durability makes them suitable for a wide range of plumbing applications. Additionally, their resistance to corrosion allows for long-term use in harsh environments, including chemical processing plants.

Role of Exporters

As the global demand for quality steel products rises, exporters play a crucial role in facilitating the distribution of high-quality A53 ERW steel pipes. These exporters often specialize in procuring pipes that comply with international standards and specifications. By ensuring quality control and providing reliable logistics, they enable manufacturers and contractors worldwide to access the materials they need.

Exporters also contribute to the development of trade relationships across countries. As nations increasingly invest in infrastructure and industrial growth, the demand for high-quality construction materials like A53 ERW pipes will continue to grow. Exporters who prioritize quality and compliance can capitalize on this opportunity by establishing themselves as trusted suppliers in the international market.

Conclusion

High-quality 12 steel pipe STD ERW A53 represents a vital component of modern manufacturing and construction industries. As the demand for reliable and durable materials increases, the role of exporters becomes ever more important in ensuring that these high-quality pipes are available globally. By focusing on quality, adherence to international standards, and robust trade practices, the industry can continue to thrive and meet the evolving needs of various sectors worldwide. Whether in structural applications or fluid transportation, A53 ERW pipes stand as a testament to the importance of quality in steel manufacturing.

-

High Quality Mild Steel Pipe Manufacturers in China for Exporting Premium Industrial Solutions

NewsAug.01,2024

-

Exploring Key Characteristics of Wholesale API Steel Pipes for Your Business Needs

NewsAug.01,2024

-

Current Wholesale Prices for ERW Steel Pipes in the Market Right Now

NewsAug.01,2024

-

Exploring the Diverse Applications and Benefits of China Round Steel Pipes in Construction and Industry

NewsAug.01,2024

-

Top Quality API 5L ERW Steel Pipe Manufacturer Offering Reliable and Durable Solutions for Your Needs

NewsAug.01,2024

-

Reliable Supplier of Premium Quality Concrete Pipes for Durable Construction Projects

NewsAug.01,2024