Welcome to attent the Tube Fair From 14 to 16 June 2023 and Wish we could meet there, do remember

that our booth number is W4E08

6 月 . 14, 2024 11:21 Back to list

Stainless steel seamless pipe supplier.

Stainless Steel Seamless Pipe Manufacturer

Stainless steel seamless pipes are widely used in various industries due to their excellent corrosion resistance, high-temperature strength, and outstanding mechanical properties. These pipes are manufactured by a process called hot rolling, which involves heating the metal to its melting point and then passing it through a series of rollers to form a seamless tube. This article will discuss the manufacturing process of stainless steel seamless pipes and the benefits they offer.

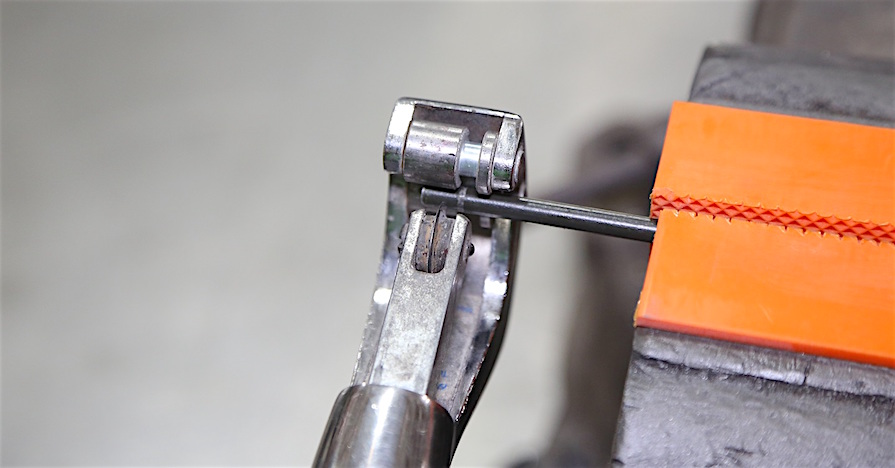

The manufacturing process of stainless steel seamless pipes begins with the selection of raw materials. High-quality stainless steel is chosen for its ability to withstand extreme temperatures and resist corrosion. The metal is then heated to its melting point in a furnace, and a hole is punched through the center of the molten metal using a piercing rod. The resulting hollow tube is then passed through a series of rollers, which gradually reduce its diameter and increase its length. Finally, the pipe is cooled and cut to the desired length.

One of the main advantages of stainless steel seamless pipes is their durability. They can withstand high pressures and temperatures without warping or cracking They can withstand high pressures and temperatures without warping or cracking They can withstand high pressures and temperatures without warping or cracking They can withstand high pressures and temperatures without warping or cracking

They can withstand high pressures and temperatures without warping or cracking They can withstand high pressures and temperatures without warping or cracking stainless steel seamless pipe manufacturer. This makes them ideal for use in industries such as oil and gas extraction, chemical processing, and power generation. Additionally, stainless steel seamless pipes are resistant to corrosion, which means they can be used in environments that would quickly degrade other types of pipes.

Another benefit of stainless steel seamless pipes is their versatility. They can be manufactured in a wide range of sizes and thicknesses to meet the specific needs of different industries. For example, smaller diameter pipes may be used in medical equipment or food processing plants, while larger diameter pipes may be used in industrial applications such as pipelines or heat exchangers.

In conclusion, stainless steel seamless pipes are an essential component of many industries due to their durability, corrosion resistance, and versatility. By understanding the manufacturing process and selecting high-quality materials, manufacturers can produce pipes that meet the demanding requirements of these industries. As technology continues to advance, we can expect further improvements in the production and performance of stainless steel seamless pipes.

stainless steel seamless pipe manufacturer. This makes them ideal for use in industries such as oil and gas extraction, chemical processing, and power generation. Additionally, stainless steel seamless pipes are resistant to corrosion, which means they can be used in environments that would quickly degrade other types of pipes.

Another benefit of stainless steel seamless pipes is their versatility. They can be manufactured in a wide range of sizes and thicknesses to meet the specific needs of different industries. For example, smaller diameter pipes may be used in medical equipment or food processing plants, while larger diameter pipes may be used in industrial applications such as pipelines or heat exchangers.

In conclusion, stainless steel seamless pipes are an essential component of many industries due to their durability, corrosion resistance, and versatility. By understanding the manufacturing process and selecting high-quality materials, manufacturers can produce pipes that meet the demanding requirements of these industries. As technology continues to advance, we can expect further improvements in the production and performance of stainless steel seamless pipes.

They can withstand high pressures and temperatures without warping or cracking They can withstand high pressures and temperatures without warping or cracking

They can withstand high pressures and temperatures without warping or cracking They can withstand high pressures and temperatures without warping or cracking stainless steel seamless pipe manufacturer. This makes them ideal for use in industries such as oil and gas extraction, chemical processing, and power generation. Additionally, stainless steel seamless pipes are resistant to corrosion, which means they can be used in environments that would quickly degrade other types of pipes.

Another benefit of stainless steel seamless pipes is their versatility. They can be manufactured in a wide range of sizes and thicknesses to meet the specific needs of different industries. For example, smaller diameter pipes may be used in medical equipment or food processing plants, while larger diameter pipes may be used in industrial applications such as pipelines or heat exchangers.

In conclusion, stainless steel seamless pipes are an essential component of many industries due to their durability, corrosion resistance, and versatility. By understanding the manufacturing process and selecting high-quality materials, manufacturers can produce pipes that meet the demanding requirements of these industries. As technology continues to advance, we can expect further improvements in the production and performance of stainless steel seamless pipes.

stainless steel seamless pipe manufacturer. This makes them ideal for use in industries such as oil and gas extraction, chemical processing, and power generation. Additionally, stainless steel seamless pipes are resistant to corrosion, which means they can be used in environments that would quickly degrade other types of pipes.

Another benefit of stainless steel seamless pipes is their versatility. They can be manufactured in a wide range of sizes and thicknesses to meet the specific needs of different industries. For example, smaller diameter pipes may be used in medical equipment or food processing plants, while larger diameter pipes may be used in industrial applications such as pipelines or heat exchangers.

In conclusion, stainless steel seamless pipes are an essential component of many industries due to their durability, corrosion resistance, and versatility. By understanding the manufacturing process and selecting high-quality materials, manufacturers can produce pipes that meet the demanding requirements of these industries. As technology continues to advance, we can expect further improvements in the production and performance of stainless steel seamless pipes. Pervious:

Latest news

-

High Quality Mild Steel Pipe Manufacturers in China for Exporting Premium Industrial Solutions

NewsAug.01,2024

-

Exploring Key Characteristics of Wholesale API Steel Pipes for Your Business Needs

NewsAug.01,2024

-

Current Wholesale Prices for ERW Steel Pipes in the Market Right Now

NewsAug.01,2024

-

Exploring the Diverse Applications and Benefits of China Round Steel Pipes in Construction and Industry

NewsAug.01,2024

-

Top Quality API 5L ERW Steel Pipe Manufacturer Offering Reliable and Durable Solutions for Your Needs

NewsAug.01,2024

-

Reliable Supplier of Premium Quality Concrete Pipes for Durable Construction Projects

NewsAug.01,2024