While iron has been in use for over 1,000 years, stainless steel is relatively new. The first stainless steel was produced around 100 years ago. In the intervening decades, it has revolutionized the modern world and is found in applications from building to healthcare to transportation.

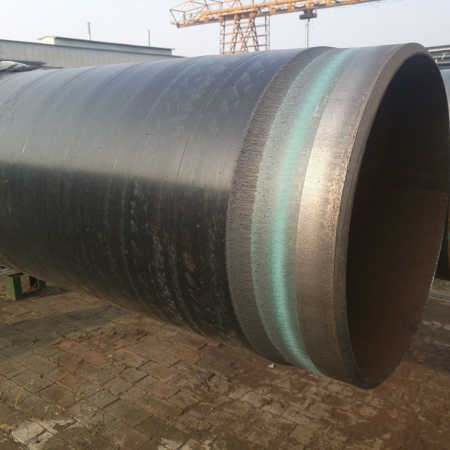

3LPE Coated Steel Pipe used in pipeline transportation

Rustless Steel

Harry Brearley invented the first true stainless steel in 1913. He added 12.8% chromium to iron, and produced a metal that he found was resistant to both corrosion and rust. Brearley discovered this metal while looking for a solution to the problem of erosion in the gun barrels of the British army.

Once stainless steel was first developed, improvements came rapidly. By 1919, a patent had been filed on marensitic stainless steel, a forerunner to today’s 410 stainless steel. In 1929, William J. Kroll discovered the process of precipitation-hardening stainless. The first duplex stainless steel was produced in Sweden in 1930.

Stainless Steel Applications

Soon after stainless steel’s discovery, it was put to work in a wide range of applications. In Sheffield, UK, where the first stainless steel was made, factories began manufacturing surgical tools and cutlery from the material. By 1925, stainless steel tanks were proving their resistance to corrosion by storing nitric acid for industrial applications. In 1926, the first surgical steel implants were used. The first beer to be fermented in stainless steel tanks was brewed in 1928. The material is now standard for the brewing industry.

Throughout the 1920s, a range of nickel and chromium formulations were tested. Different mixes presented different benefits in corrosion resistance, malleability and other qualities. There are now roughly 100 grades of stainless steel commercially available. Stainless steel grades fall into four general groups: martensitic, austentic, duplex and ferritic. Ferritic and martensitic are magnetic while austentic and duplex are not.

Many famous landmarks, such as the sculpture above the entrance of 50 Rockefeller Plaza and Chicago’s Could Gate, get their luster from stainless steel. Stainless steel was put to work in applications that included tidal power plants in the 1960s and flood barriers by the 1980s.

Stainless Steel Today

As we look toward future challenges, stainless steel remains an ideal material. Stainless steel is 100% recyclable and can be reprocessed without degradation, which keeps it out of the waste stream. It is highly resistant to corrosion, which means it has a long service life before needing replacement. Together, these qualities can help with the task of reducing carbon emissions and forging more sustainable practices.