Welcome to attent the Tube Fair From 14 to 16 June 2023 and Wish we could meet there, do remember

that our booth number is W4E08

6 月 . 12, 2024 19:41 Back to list

Providers of API steel pipe welding services

API Steel Pipe Welding Suppliers A Comprehensive Overview

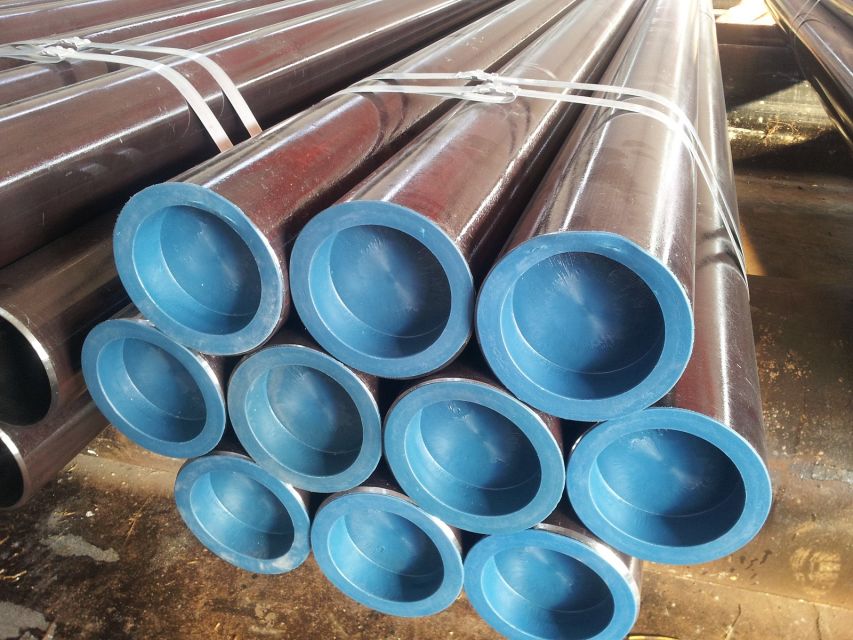

In the world of industrial piping systems, API (American Petroleum Institute) steel pipes hold a significant position due to their durability, strength, and resistance to harsh environmental conditions. These pipes, predominantly used in oil and gas industries, are manufactured by a network of reputable suppliers who specialize in welding and fabrication processes.

API steel pipe welding suppliers are the backbone of the industry, ensuring that the pipes meet stringent standards set forth by the API. They are responsible for sourcing high-quality raw materials, implementing advanced welding techniques, and providing post-weld treatments to guarantee optimal performance and longevity. Their expertise lies in fabricating pipes that can withstand extreme pressures, temperatures, and corrosion, making them ideal for transporting crude oil, natural gas, and other petrochemical products.

One key aspect of API steel pipe welding is the use of specialized welding methods like submerged arc welding (SAW), electroslag welding (ESW), and gas metal arc welding (GMAW). These techniques ensure strong, seamless welds that minimize the risk of leaks or structural failure. Additionally, suppliers often employ non-destructive testing (NDT) methods such as ultrasonic testing, radiography, and visual inspection to ensure the integrity of the welds.

API steel pipe welding suppliers also cater to custom requirements, offering pipes in various sizes, grades, and lengths. From API 5L Gr From API 5L Gr From API 5L Gr From API 5L Gr

From API 5L Gr From API 5L Gr api steel pipe welding suppliers. B to X70, these suppliers provide a wide range of steel grades to accommodate different project needs. Moreover, they often provide ancillary services like pipe cutting, threading, and coating to streamline the installation process for their clients.

When selecting an API steel pipe welding supplier, it's crucial to consider factors such as their compliance with international standards, quality certifications, manufacturing capabilities, and their track record in the industry. A reliable supplier should have a robust quality management system, ensuring adherence to API specifications, and be able to deliver on time while maintaining consistent product quality.

In conclusion, API steel pipe welding suppliers play a pivotal role in the global energy sector. Their commitment to precision, safety, and innovation ensures that the infrastructure supporting our energy needs remains robust and efficient. As the demand for sustainable and efficient energy solutions grows, these suppliers continue to evolve, embracing new technologies and practices to stay at the forefront of the industry.

api steel pipe welding suppliers. B to X70, these suppliers provide a wide range of steel grades to accommodate different project needs. Moreover, they often provide ancillary services like pipe cutting, threading, and coating to streamline the installation process for their clients.

When selecting an API steel pipe welding supplier, it's crucial to consider factors such as their compliance with international standards, quality certifications, manufacturing capabilities, and their track record in the industry. A reliable supplier should have a robust quality management system, ensuring adherence to API specifications, and be able to deliver on time while maintaining consistent product quality.

In conclusion, API steel pipe welding suppliers play a pivotal role in the global energy sector. Their commitment to precision, safety, and innovation ensures that the infrastructure supporting our energy needs remains robust and efficient. As the demand for sustainable and efficient energy solutions grows, these suppliers continue to evolve, embracing new technologies and practices to stay at the forefront of the industry.

From API 5L Gr From API 5L Gr

From API 5L Gr From API 5L Gr api steel pipe welding suppliers. B to X70, these suppliers provide a wide range of steel grades to accommodate different project needs. Moreover, they often provide ancillary services like pipe cutting, threading, and coating to streamline the installation process for their clients.

When selecting an API steel pipe welding supplier, it's crucial to consider factors such as their compliance with international standards, quality certifications, manufacturing capabilities, and their track record in the industry. A reliable supplier should have a robust quality management system, ensuring adherence to API specifications, and be able to deliver on time while maintaining consistent product quality.

In conclusion, API steel pipe welding suppliers play a pivotal role in the global energy sector. Their commitment to precision, safety, and innovation ensures that the infrastructure supporting our energy needs remains robust and efficient. As the demand for sustainable and efficient energy solutions grows, these suppliers continue to evolve, embracing new technologies and practices to stay at the forefront of the industry.

api steel pipe welding suppliers. B to X70, these suppliers provide a wide range of steel grades to accommodate different project needs. Moreover, they often provide ancillary services like pipe cutting, threading, and coating to streamline the installation process for their clients.

When selecting an API steel pipe welding supplier, it's crucial to consider factors such as their compliance with international standards, quality certifications, manufacturing capabilities, and their track record in the industry. A reliable supplier should have a robust quality management system, ensuring adherence to API specifications, and be able to deliver on time while maintaining consistent product quality.

In conclusion, API steel pipe welding suppliers play a pivotal role in the global energy sector. Their commitment to precision, safety, and innovation ensures that the infrastructure supporting our energy needs remains robust and efficient. As the demand for sustainable and efficient energy solutions grows, these suppliers continue to evolve, embracing new technologies and practices to stay at the forefront of the industry. Latest news

-

High Quality Mild Steel Pipe Manufacturers in China for Exporting Premium Industrial Solutions

NewsAug.01,2024

-

Exploring Key Characteristics of Wholesale API Steel Pipes for Your Business Needs

NewsAug.01,2024

-

Current Wholesale Prices for ERW Steel Pipes in the Market Right Now

NewsAug.01,2024

-

Exploring the Diverse Applications and Benefits of China Round Steel Pipes in Construction and Industry

NewsAug.01,2024

-

Top Quality API 5L ERW Steel Pipe Manufacturer Offering Reliable and Durable Solutions for Your Needs

NewsAug.01,2024

-

Reliable Supplier of Premium Quality Concrete Pipes for Durable Construction Projects

NewsAug.01,2024