7 月 . 29, 2024 23:58 Back to list

Overview of Steel Pipe Manufacturing Facilities and Their Role in Construction Industry

The Importance of Construction Steel Pipe Factories

In the modern construction industry, the demand for durable and reliable materials is incessantly on the rise. Among these materials, steel pipes have carved out an indispensable niche owing to their strength, versatility, and longevity. Construction steel pipe factories play a pivotal role in supplying these essential components, underpinning the construction of infrastructure, buildings, and various industrial projects.

Steel pipes are widely used in numerous applications, including plumbing, infrastructure development, and manufacturing. They provide a robust solution for conveying fluids, gases, and even solids, thanks to their high tensile strength and resistance to environmental factors. The ability to withstand high pressures and extreme temperatures makes steel pipes ideal for a range of applications from oil and gas extraction to water supply systems.

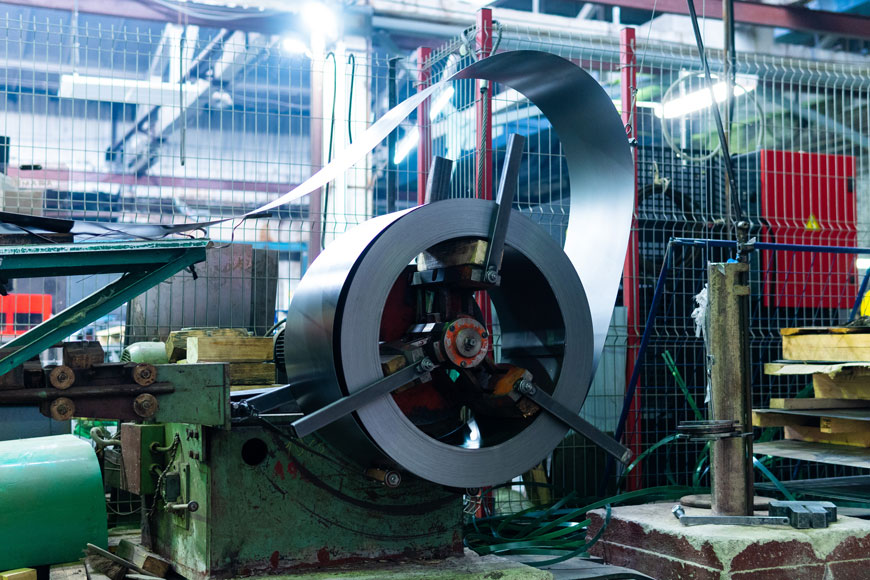

The operation of construction steel pipe factories involves several critical processes, including the sourcing of raw materials, manufacturing, quality control, and distribution. The production begins with the procurement of high-quality steel, often sourced from recycled materials, which aligns with sustainable practices in modern manufacturing. This not only promotes ecological responsibility but also ensures that the steel pipes produced are resilient and meet international standards.

The manufacturing phase involves several methods, including seamless and welded pipe production. Seamless pipes are formed from a solid piece of steel, making them ideal for high-pressure applications. On the other hand, welded pipes are made by joining two edges of steel sheets, a process that is efficient and cost-effective for projects requiring large diameters. Each method has its unique advantages, and the choice often depends on the specific requirements of the construction project.

construction steel pipe factories

Quality control is a significant aspect of operations in steel pipe factories. To ensure that the pipes meet stringent safety and durability standards, they undergo rigorous testing for factors such as strength, corrosion resistance, and ductility. Advanced technologies, including non-destructive testing methods, are employed to detect any potential flaws in the pipes. This commitment to quality guarantees that the end product can be relied upon in critical construction applications.

Moreover, the logistics and distribution of steel pipes are crucial for timely project execution. Construction steel pipe factories have to optimize their supply chains to ensure that large quantities of pipes can be delivered efficiently to various sites. This involves collaboration with transportation companies and managing inventory levels to meet the fluctuating demands of the construction industry.

Furthermore, the role of technology in construction steel pipe factories cannot be overstated. Automation and digitization have transformed traditional manufacturing processes, enhancing efficiency and reducing production times. The adoption of advanced manufacturing techniques such as 3D printing, robotics, and artificial intelligence is ushering in a new era of productivity. These technologies not only streamline operations but also minimize waste, further contributing to sustainability efforts.

In conclusion, construction steel pipe factories are critical to the ongoing growth and stability of the construction industry. By providing reliable and high-quality steel pipes, these factories support a wide range of applications that are essential for modern infrastructure and industrial development. As the industry evolves, embracing technological advancements and sustainable practices will ensure the continued relevance and efficiency of steel pipe manufacturing. The future promises exciting developments, further solidifying the importance of construction steel pipe factories in meeting the challenges of tomorrow’s construction demands.

-

High Quality Mild Steel Pipe Manufacturers in China for Exporting Premium Industrial Solutions

NewsAug.01,2024

-

Exploring Key Characteristics of Wholesale API Steel Pipes for Your Business Needs

NewsAug.01,2024

-

Current Wholesale Prices for ERW Steel Pipes in the Market Right Now

NewsAug.01,2024

-

Exploring the Diverse Applications and Benefits of China Round Steel Pipes in Construction and Industry

NewsAug.01,2024

-

Top Quality API 5L ERW Steel Pipe Manufacturer Offering Reliable and Durable Solutions for Your Needs

NewsAug.01,2024

-

Reliable Supplier of Premium Quality Concrete Pipes for Durable Construction Projects

NewsAug.01,2024