8 月 . 01, 2024 01:58 Back to list

Manufacturers of Hot-Dip Galvanized ERW Steel Pipes for Reliable Construction Applications and Standards

The Rise of Dip Galvanized ERW Steel Pipe Manufacturers

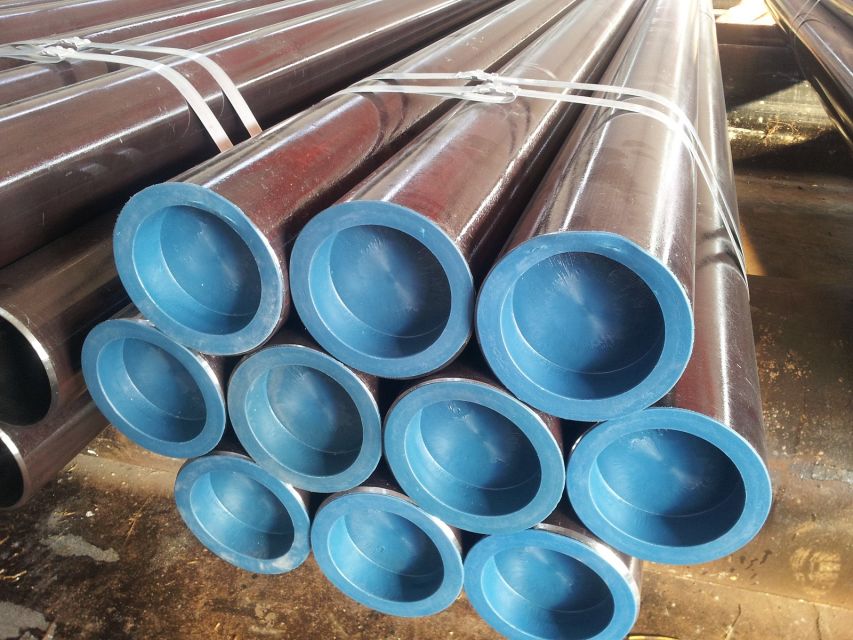

In recent years, the construction and manufacturing industries have increasingly relied on high-quality steel products. Among these, Electric Resistance Welded (ERW) steel pipes have gained significant popularity due to their versatility and strength. When combined with dip galvanization, these pipes offer enhanced corrosion resistance, making them exceptionally suitable for various applications, from infrastructure projects to oil and gas transportation.

Understanding ERW Steel Pipes

Electric Resistance Welded (ERW) steel pipes are produced by rolling flat steel sheets into a cylindrical shape and then welding the edges together using a high-frequency electric current. This process creates a strong seam that can support a range of mechanical and pressure applications. ERW pipes are favored for their consistency in wall thickness, dimensional accuracy, and overall structural integrity.

The manufacturing of ERW pipes involves sophisticated technology and processes that ensure high quality and durability. However, one of the primary challenges faced by ERW pipes is their susceptibility to corrosion, particularly when exposed to harsh environmental conditions.

The Benefits of Dip Galvanization

To combat corrosion, dip galvanization is a widely used technique that involves immersing steel pipes in molten zinc. This process forms a protective layer on the surface of the pipes, significantly extending their lifespan and performance. The advantages of dip galvanized ERW steel pipes include

dip galvanized erw steel pipe manufacturer

2. Durability The coating not only protects against rust but also provides a tough exterior that is resistant to scratches and impacts, ensuring the longevity of the pipe.

3. Low Maintenance With their enhanced protection, dip galvanized ERW pipes require less maintenance compared to their uncoated counterparts. This feature is particularly beneficial in industrial settings where regular upkeep can be time-consuming and costly.

4. Cost-Effectiveness While the initial cost of dip galvanization may be higher, the long-term savings due to reduced maintenance and replacement needs make galvanized ERW pipes a cost-effective solution.

The Role of Manufacturers

The growing demand for dip galvanized ERW steel pipes has led to the emergence of numerous manufacturers specializing in this niche market. These manufacturers are committed to producing high-quality products that meet stringent international standards. They invest in state-of-the-art technology and skilled labor to ensure that their pipes not only meet but exceed customer expectations.

Moreover, many manufacturers are now focusing on sustainable practices. This includes optimizing the galvanization process to minimize waste and utilizing energy-efficient machinery. By adopting green manufacturing processes, these companies contribute positively to the environment while producing superior quality goods.

Conclusion

In summary, the combination of dip galvanization and ERW steel pipes represents a significant advancement in materials engineering. Manufacturers in this sector play a crucial role by providing products that meet the demands of modern construction and infrastructure projects. As industries continue to prioritize sustainability and performance, the popularity of dip galvanized ERW steel pipes is likely to grow. With ongoing advancements in manufacturing technology and a focus on quality, the future looks bright for both manufacturers and users of these essential materials. The rise of dip galvanized ERW steel pipes not only addresses immediate engineering needs but also enhances the longevity and reliability of critical infrastructure worldwide.

-

High Quality Mild Steel Pipe Manufacturers in China for Exporting Premium Industrial Solutions

NewsAug.01,2024

-

Exploring Key Characteristics of Wholesale API Steel Pipes for Your Business Needs

NewsAug.01,2024

-

Current Wholesale Prices for ERW Steel Pipes in the Market Right Now

NewsAug.01,2024

-

Exploring the Diverse Applications and Benefits of China Round Steel Pipes in Construction and Industry

NewsAug.01,2024

-

Top Quality API 5L ERW Steel Pipe Manufacturer Offering Reliable and Durable Solutions for Your Needs

NewsAug.01,2024

-

Reliable Supplier of Premium Quality Concrete Pipes for Durable Construction Projects

NewsAug.01,2024