7 月 . 29, 2024 22:51 Back to list

Leading Manufacturer for Wholesale Supply of High-Quality Steel Pipes and Tubes Worldwide

Wholesale Steel Pipe Supply Manufacturer An Essential Player in the Industry

In today's industrial landscape, the demand for robust and reliable materials is always on the rise, particularly in sectors such as construction, infrastructure development, oil and gas, and manufacturing. One of the key components that plays a crucial role in these industries is steel pipe. As a wholesale steel pipe supply manufacturer, the responsibility goes beyond just production; it encompasses quality assurance, supply chain efficiency, and meeting the diverse needs of clients across various sectors.

Understanding Steel Pipes and Their Importance

Steel pipes are essential components used in a myriad of applications ranging from transporting fluids and gases to structural purposes in buildings and frameworks. They come in various sizes, materials, and specifications tailored to meet specific industrial needs. The versatility of steel pipes is one of the reasons they are favored in both residential and commercial applications. Furthermore, steel pipes offer superior strength, durability, and resistance to corrosion when treated correctly, making them ideal for challenging environments.

The Role of Wholesale Manufacturers

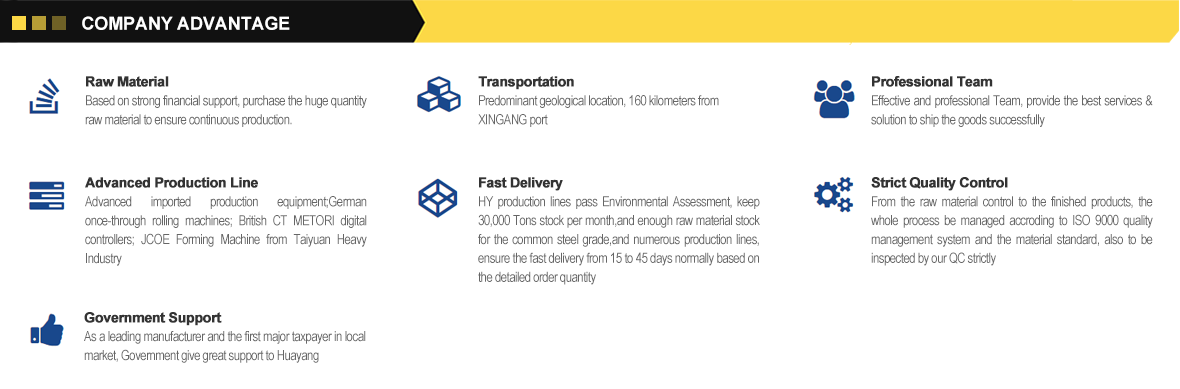

Wholesale manufacturers of steel pipes operate at the core of this industry, providing high volumes of products to distributors, contractors, and other businesses. Their role is not merely as suppliers but as partners in the supply chain. They ensure that quality materials are available in sufficient quantity and at competitive prices, which is vital for companies that need to manage their costs effectively.

Wholesale steel pipe manufacturers typically offer a wide range of products, including seamless and welded pipes, along with specialty pipes designed for specific applications. This variety allows clients to find the precise products they need, which can greatly influence the efficiency and effectiveness of their operations.

Quality and Standards

wholesale steel pipe supply manufacturer

One of the critical aspects of a reputable wholesale steel pipe manufacturer is adherence to quality standards. Quality assurance protocols must be in place throughout the production process—from raw material selection to final inspection before shipment. Many manufacturers comply with international standards such as ASTM, ISO, and API, ensuring that their products not only meet but exceed industry expectations.

Moreover, manufacturers often engage in rigorous testing, including hydrostatic testing, ultrasonic testing, and visual inspection, to ensure that their pipes can withstand the pressures and stresses they will encounter in use. By prioritizing quality, manufacturers help their clients mitigate risks related to pipe failures, which can lead to costly downtime and safety hazards.

Sustainability Practices

With growing concerns over environmental issues, many wholesale steel pipe supply manufacturers are adopting sustainable practices. This includes sourcing recyclable materials, reducing waste during production, and implementing energy-efficient practices within their operations. By adopting a more sustainable approach, these manufacturers not only contribute to environmental preservation but also position themselves as responsible leaders in the industry.

Customer-Centric Approach

Understanding that each client comes with unique requirements, successful wholesale manufacturers take a customer-centric approach. This may include offering customized solutions, providing technical support, and maintaining a flexible inventory to accommodate fluctuating demand. Building long-term relationships based on trust and reliability is crucial for manufacturers aiming to thrive in a competitive market.

Conclusion

In summary, wholesale steel pipe supply manufacturers play a vital role in ensuring the smooth operation of numerous industries. By focusing on quality, adhering to industry standards, embracing sustainability, and prioritizing customer service, these manufacturers not only contribute to the efficiency of supply chains but also to the overall progress of industrial applications worldwide. As the global demand for steel pipes continues to grow, these manufacturers will undoubtedly remain key players in shaping the future of infrastructure development.

-

High Quality Mild Steel Pipe Manufacturers in China for Exporting Premium Industrial Solutions

NewsAug.01,2024

-

Exploring Key Characteristics of Wholesale API Steel Pipes for Your Business Needs

NewsAug.01,2024

-

Current Wholesale Prices for ERW Steel Pipes in the Market Right Now

NewsAug.01,2024

-

Exploring the Diverse Applications and Benefits of China Round Steel Pipes in Construction and Industry

NewsAug.01,2024

-

Top Quality API 5L ERW Steel Pipe Manufacturer Offering Reliable and Durable Solutions for Your Needs

NewsAug.01,2024

-

Reliable Supplier of Premium Quality Concrete Pipes for Durable Construction Projects

NewsAug.01,2024