7 月 . 27, 2024 19:37 Back to list

Finding Reliable Manufacturers for Steel Pipe Supply and Their Quality Assurance Processes

The Importance of Steel Pipe Supply Factories in Modern Industry

Steel pipe supply factories play a pivotal role in the modern industrial landscape. These facilities are critical in providing a range of steel pipes and tubes that are essential for various applications, including construction, manufacturing, and energy production. As global infrastructure grows and evolves, the demand for high-quality steel pipes continues to rise, underscoring the importance of these factories in the supply chain.

Understanding Steel Pipes

Steel pipes are hollow, cylindrical shapes made from rolled steel. They come in various diameters and wall thicknesses, serving different purposes across industries. Some of the most common types of steel pipes include seamless pipes, welded pipes, and structural pipes. They are primarily used in plumbing, heating, oil and gas transportation, and in the construction of buildings and infrastructure.

The properties of steel—its strength, durability, and resistance to corrosion—make it an ideal choice for pipe manufacturing. These characteristics ensure that steel pipes can withstand high pressures and extreme temperatures, which are common in industrial applications. As such, reliable steel pipe supply factories are crucial to meet the stringent quality and safety standards required across these sectors.

The Production Process

The production of steel pipes involves several key steps, each of which is critical to ensuring the final product meets industry standards. Initially, raw materials, primarily iron ore and scrap steel, are melted in large furnaces. Once the steel reaches the desired temperature and consistency, it is molded and formed into pipes through various processes.

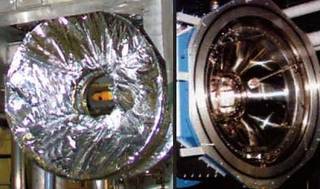

Seamless pipes are formed by piercing a solid billet and elongating it to the desired size, resulting in a pipe without any welded seams. This method is ideal for high-pressure applications. On the other hand, welded pipes are created by rolling a flat sheet of steel into a cylindrical shape and welding the edges together. The choice between seamless and welded pipes often depends on the specific application and the environmental conditions in which the pipes will be used.

steel pipe supply factories

Quality Assurance and Standards

Given the critical applications of steel pipes, quality assurance is paramount. Steel pipe supply factories must adhere to strict industry standards such as ASTM (American Society for Testing and Materials) and API (American Petroleum Institute) specifications. These standards help ensure the pipes can withstand the rigors of their intended applications.

Quality control involves rigorous testing at various stages of production. This includes checking the chemical composition of the steel, testing for mechanical properties, and conducting non-destructive testing to identify any defects. Such comprehensive quality assurance processes ensure that the final products are reliable and safe for use.

Economic Impact

Steel pipe supply factories contribute significantly to the economy. They not only provide employment opportunities but also stimulate growth in related industries. As construction and transportation sectors expand, the demand for steel pipes will continue to increase, encouraging factories to innovate and improve their manufacturing processes.

Moreover, as sustainability becomes a focal point in industrial practices, many factories are adopting eco-friendly manufacturing techniques. This includes recycling scrap metal and minimizing waste, thereby contributing to a circular economy.

Conclusion

In conclusion, steel pipe supply factories are fundamental to various industries, providing the essential materials needed for infrastructure and development projects worldwide. With ongoing advancements in production technology and a growing emphasis on quality and sustainability, these factories are poised to meet the needs of a rapidly evolving industrial landscape. As we continue to build and innovate, the importance of reliable steel pipe supply will remain a cornerstone of modern industry.

-

High Quality Mild Steel Pipe Manufacturers in China for Exporting Premium Industrial Solutions

NewsAug.01,2024

-

Exploring Key Characteristics of Wholesale API Steel Pipes for Your Business Needs

NewsAug.01,2024

-

Current Wholesale Prices for ERW Steel Pipes in the Market Right Now

NewsAug.01,2024

-

Exploring the Diverse Applications and Benefits of China Round Steel Pipes in Construction and Industry

NewsAug.01,2024

-

Top Quality API 5L ERW Steel Pipe Manufacturer Offering Reliable and Durable Solutions for Your Needs

NewsAug.01,2024

-

Reliable Supplier of Premium Quality Concrete Pipes for Durable Construction Projects

NewsAug.01,2024