7 月 . 27, 2024 07:09 Back to list

Exploring the Benefits and Applications of High-Quality Hollow Steel Structures in Modern Engineering

High-Quality Hollow Sections An Overview

In the realm of construction and manufacturing, materials play a pivotal role in determining the strength, durability, and overall performance of structures. Among various materials, hollow sections, particularly those of high quality, have gained prominence for their exceptional properties and versatility. This article explores the significance, benefits, applications, and manufacturing processes pertaining to high-quality hollow sections.

Understanding Hollow Sections

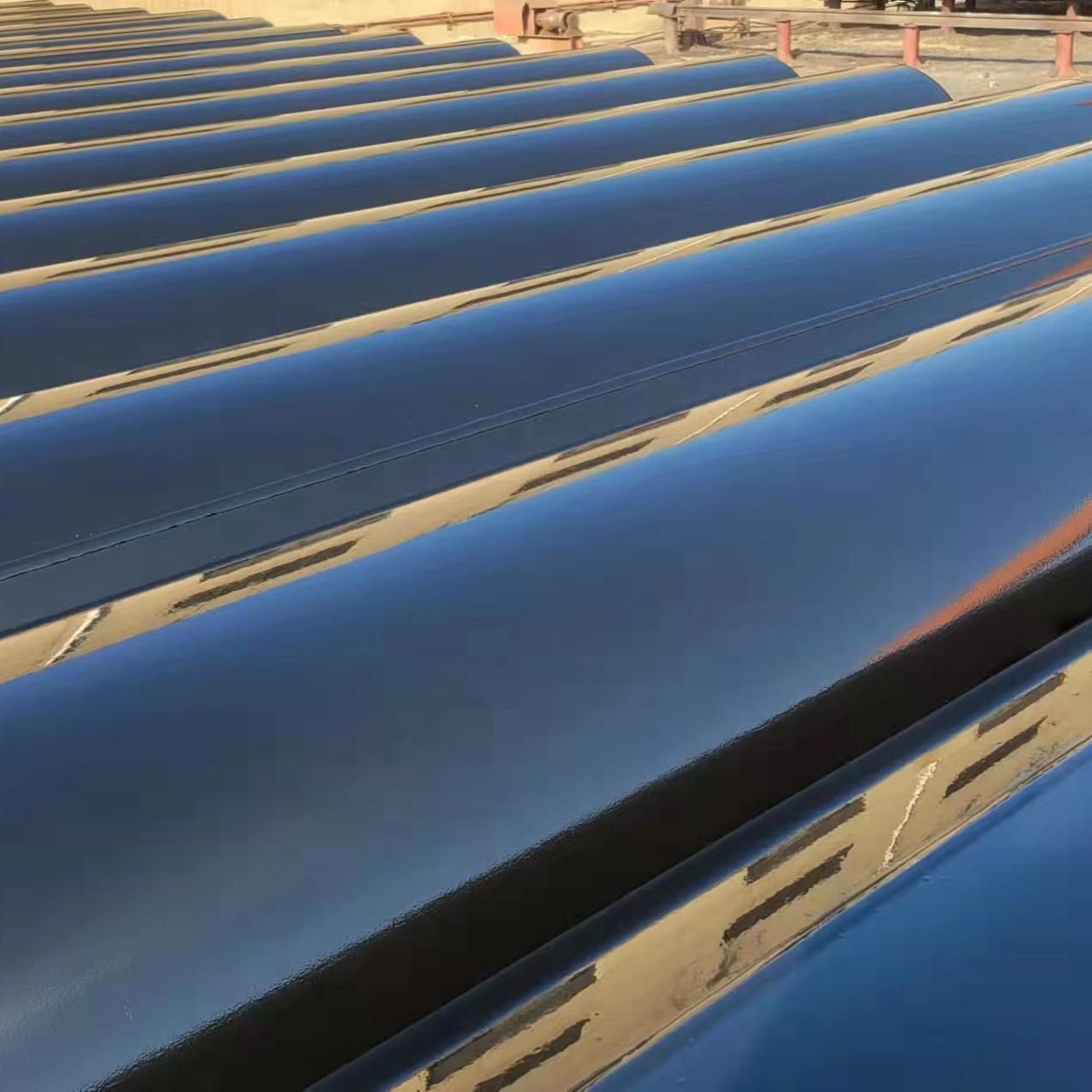

Hollow sections refer to structural steel sections that have a hollow profile, commonly cylindrical or rectangular in shape. They are especially valued for their strength-to-weight ratio, making them an ideal choice in construction and engineering applications. High-quality hollow sections are produced using advanced techniques, ensuring that they meet rigorous standards in terms of composition, mechanical properties, and surface finish.

Benefits of High-Quality Hollow Sections

1. Strength and Durability High-quality hollow sections are designed to withstand significant loads and stresses, making them suitable for use in critical structural applications. Their robust nature ensures longevity, reducing the need for frequent replacements or repairs.

2. Lightweight Design One of the major advantages of hollow sections is their lightweight nature. This characteristic allows for easier handling and installation compared to traditional solid sections, while still providing the necessary strength and stability in structures.

3. Aesthetic Appeal The sleek lines and uniform profiles of hollow sections contribute to modern architectural designs. They can be used creatively to enhance the aesthetics of buildings and structures, allowing for innovative design solutions.

high quality hollow section

4. Versatile Applications High-quality hollow sections are used across various industries, including construction, automotive, and manufacturing. They are pivotal in building frameworks, bridges, and machinery, among other applications.

5. Cost-Effectiveness Although the initial cost of high-quality hollow sections may be higher than that of lower-quality alternatives, their durability and minimal maintenance needs lead to overall cost savings in the long run.

Applications of High-Quality Hollow Sections

High-quality hollow sections are utilized in a multitude of structures and applications. In the construction industry, they serve as essential components in building frameworks, offering both strength and aesthetic value. Bridges commonly incorporate hollow sections to enhance structural integrity while minimizing weight. In the automotive sector, they are often used in vehicle frames and chassis, contributing to lighter, stronger designs. Additionally, high-quality hollow sections find their place in machinery and equipment, where strength and weight considerations are paramount.

Manufacturing Processes

The production of high-quality hollow sections involves advanced manufacturing processes. Typically, the process begins with high-grade raw materials, including steel billets and coils. These materials undergo processes like hot-rolling or cold-forming, where they are shaped into the desired profile. Subsequently, techniques such as welding or seam formation are employed to create the hollow structure. Stringent testing and quality control measures ensure that the final product meets all necessary specifications and standards.

Conclusion

High-quality hollow sections play a critical role in modern engineering and construction. Their unique combination of strength, lightweight design, and aesthetic appeal makes them an indispensable choice in various applications. As the demand for innovative and durable building materials continues to rise, the popularity of high-quality hollow sections is expected to soar. Their ongoing development and refinement ensure that they remain at the forefront of material science in the years to come.

-

High Quality Mild Steel Pipe Manufacturers in China for Exporting Premium Industrial Solutions

NewsAug.01,2024

-

Exploring Key Characteristics of Wholesale API Steel Pipes for Your Business Needs

NewsAug.01,2024

-

Current Wholesale Prices for ERW Steel Pipes in the Market Right Now

NewsAug.01,2024

-

Exploring the Diverse Applications and Benefits of China Round Steel Pipes in Construction and Industry

NewsAug.01,2024

-

Top Quality API 5L ERW Steel Pipe Manufacturer Offering Reliable and Durable Solutions for Your Needs

NewsAug.01,2024

-

Reliable Supplier of Premium Quality Concrete Pipes for Durable Construction Projects

NewsAug.01,2024