Welcome to attent the Tube Fair From 14 to 16 June 2023 and Wish we could meet there, do remember

that our booth number is W4E08

7 月 . 11, 2024 02:16 Back to list

Establishing a Factory for Manufacturing Pipe Bends in Construction Industry

The construction of a pipe bends factory is a significant endeavor that involves careful planning and execution to ensure the success of the project. Pipe bends are an essential component in various industries, including oil and gas, construction, and manufacturing, and having a dedicated factory for their production can streamline the manufacturing process and improve overall efficiency.

The first step in the construction of a pipe bends factory is to identify a suitable location for the facility. Factors such as proximity to raw materials, access to transportation routes, and availability of skilled labor should be considered when selecting a site for the factory. Additionally, the size of the facility should be determined based on the projected production capacity and future growth plans.

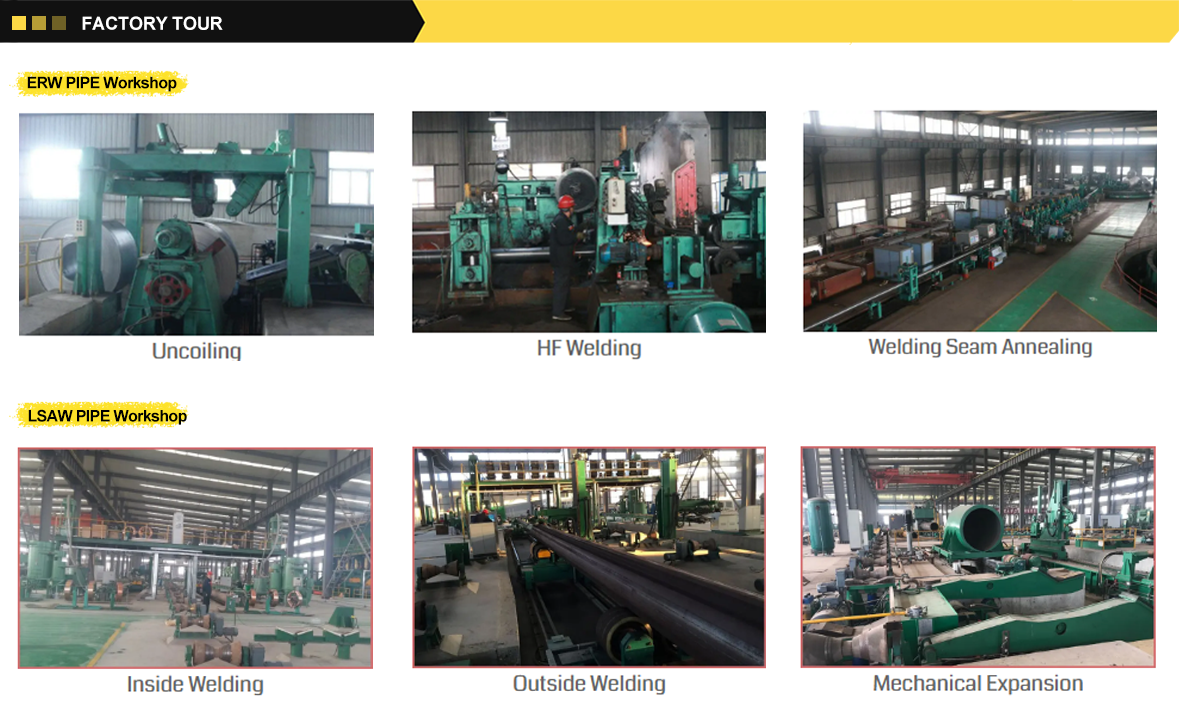

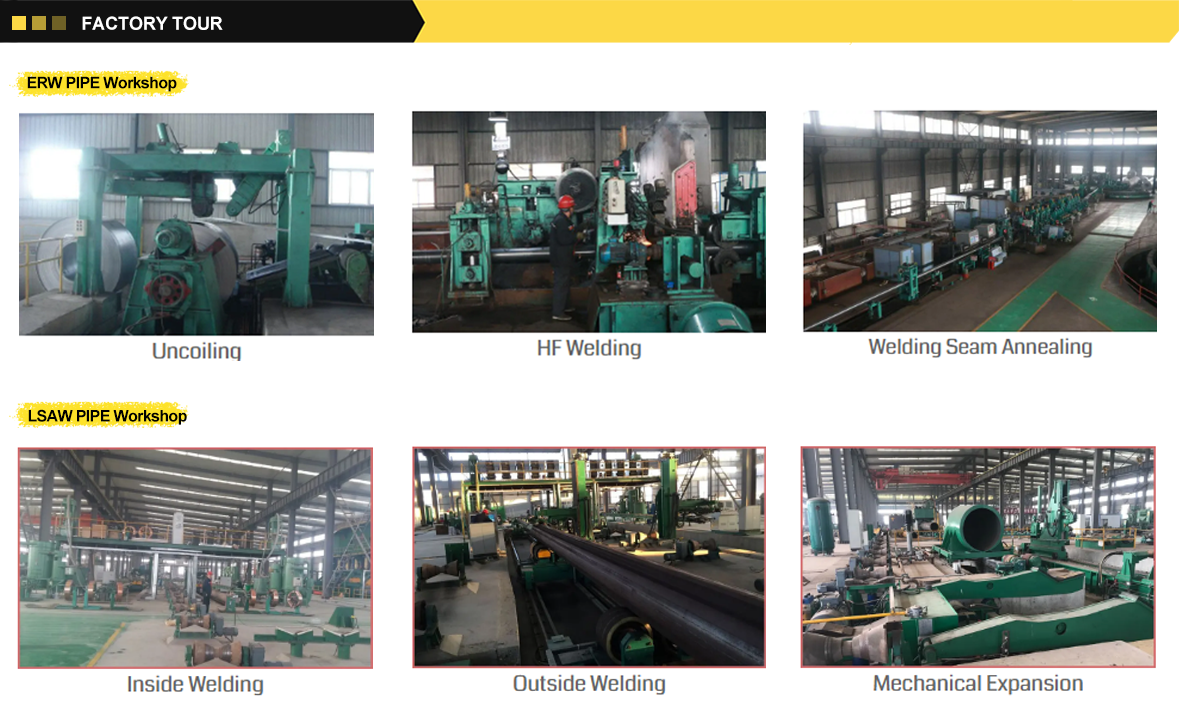

Once a location has been chosen, the next step is to design the layout of the factory, taking into account the flow of materials and equipment to optimize production efficiency. The factory should be equipped with state-of-the-art machinery and technology to ensure the highest quality of pipe bends are produced. A well-designed factory layout can minimize production bottlenecks and reduce the risk of accidents or errors during the manufacturing process.

In addition to the physical construction of the factory, careful attention should be paid to the recruitment and training of staff

construction of pipe bends factory. Skilled workers are essential for the successful operation of the factory, and providing comprehensive training programs can help ensure that employees are proficient in their roles. Additionally, a strong focus on safety protocols and quality control measures should be implemented to maintain a high standard of production. The construction of a pipe bends factory requires a significant investment of time and resources, but the benefits of having a dedicated facility for their production are numerous. By centralizing production in a factory setting, companies can increase their output, reduce production costs, and improve overall product quality. Additionally, having a factory dedicated to pipe bends can help companies better meet customer demand and respond to market fluctuations more effectively. In conclusion, the construction of a pipe bends factory is a complex process that requires careful planning and execution. By selecting a suitable location, designing an efficient layout, and investing in state-of-the-art technology and training, companies can establish a successful factory for the production of pipe bends. With a dedicated facility, companies can enhance their manufacturing capabilities, improve product quality, and stay competitive in the global market.

construction of pipe bends factory. Skilled workers are essential for the successful operation of the factory, and providing comprehensive training programs can help ensure that employees are proficient in their roles. Additionally, a strong focus on safety protocols and quality control measures should be implemented to maintain a high standard of production. The construction of a pipe bends factory requires a significant investment of time and resources, but the benefits of having a dedicated facility for their production are numerous. By centralizing production in a factory setting, companies can increase their output, reduce production costs, and improve overall product quality. Additionally, having a factory dedicated to pipe bends can help companies better meet customer demand and respond to market fluctuations more effectively. In conclusion, the construction of a pipe bends factory is a complex process that requires careful planning and execution. By selecting a suitable location, designing an efficient layout, and investing in state-of-the-art technology and training, companies can establish a successful factory for the production of pipe bends. With a dedicated facility, companies can enhance their manufacturing capabilities, improve product quality, and stay competitive in the global market.

Latest news

-

High Quality Mild Steel Pipe Manufacturers in China for Exporting Premium Industrial Solutions

NewsAug.01,2024

-

Exploring Key Characteristics of Wholesale API Steel Pipes for Your Business Needs

NewsAug.01,2024

-

Current Wholesale Prices for ERW Steel Pipes in the Market Right Now

NewsAug.01,2024

-

Exploring the Diverse Applications and Benefits of China Round Steel Pipes in Construction and Industry

NewsAug.01,2024

-

Top Quality API 5L ERW Steel Pipe Manufacturer Offering Reliable and Durable Solutions for Your Needs

NewsAug.01,2024

-

Reliable Supplier of Premium Quality Concrete Pipes for Durable Construction Projects

NewsAug.01,2024