12 月 . 22, 2023 17:06 Back to list

Different Types of Carbon Steel And Carbon Steel Pipe

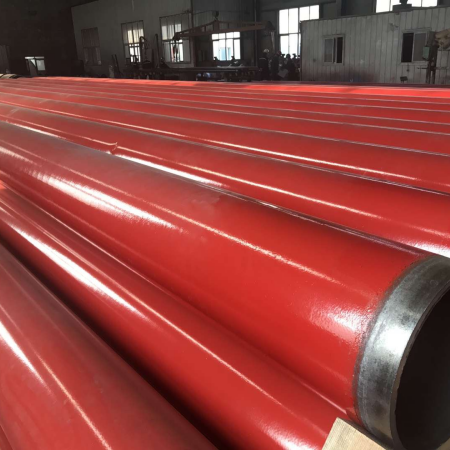

Carbon steel and Carbon steel tubes come in various types, with specific carbon steel tube dimensions suited for different applications. The primary factor that differentiates the carbon steel is the amount of carbon content and additional alloying elements. The different carbon steel pipes for sale are different according to different technology.

Carbon Steel and Carbon Steel Pipes

There are three types of carbon steel, which can be used to make carbon steel tube materials. They are low carbon steel, Medium carbon steel and high carbon steel. The pipe made from low carbon steel also called mild steel pipe. The composition of this pipe is not complicated. It contains a low amount of carbon (typically 0.05-0.25%). It has many properties and it is relatively soft and easy to form. It is for general purposes like carbon steel water pipes and structural applications. Medium Carbon Steel contains a higher amount of carbon (0.25-0.60%). It offers a balance between strength and ductility. High carbon steel contains a higher amount of carbon (0.60-1.0%). It is very strong and hard but less ductile.

Carbon Steel Seamless Pipes:

Seamless steel pipes are manufactured without a welded seam, resulting in a smooth bore and uniform diameter. This uniformity provides excellent strength and high-pressure resistance, making seamless tubes ideal for high-stress applications. They are used when high strength and enhanced corrosion resistance are required, such as in high-pressure applications.

Carbon Steel Welded Pipes:

They are produced by welding two ends of steel sheets or strips together. Compared with seamless pipes, these pipes are cost-effective and can produce larger diameters. Welded steel tubes are commonly used in medium and low-pressure applications, such as water and gas transport, structural and mechanical applications, and general industrial applications.

LSAW Steel Pipes

Longitudinal submerged arc welded (LSAW) steel pipe is made by bending steel plates and welding long seams by submerged arc welding process. The pipeline produced by this method has a straight single longitudinal seam, which is an ideal choice for large diameter and thick wall pipelines. LSAW steel pipes are commonly used in oil and gas industries, water pipelines and structural applications.

Spiral Welded Steel Pipes

Spiral welded steel pipes are produced by winding steel coil on mandrel and welding spiral seams by submerged arc welding process. This method results in continuous spiral joints in the pipe, which is suitable for large diameter and high pressure applications. Spirally welded pipes are commonly used in oil and gas industries, water pipelines and architectural engineering.

You can click https://www.huayangsteel.com/contactus.html to contact us for carbon steel pipes.

-

Stainless steel-Differences Between ERW and EFW Steel Pipe

NewsJan.30,2024

-

Stainless steel-Types Of Welded Steel Pipes

NewsJan.29,2024

-

Stainless steel-Do You Know Anything About Carbon Steel Pipe Wall Thickness?

NewsJan.19,2024

-

Stainless steel-How to Purge Welded Steel Pipe?

NewsJan.18,2024

-

Carbon Steel Tube Pressure Rating-steel pie

NewsJan.16,2024

-

Stainless steel-Electric Resistance Welded (ERW) Pipe-Welded (ERW) Pipe

NewsJan.16,2024