Welcome to attent the Tube Fair From 14 to 16 June 2023 and Wish we could meet there, do remember

that our booth number is W4E08

6 月 . 12, 2024 19:35 Back to list

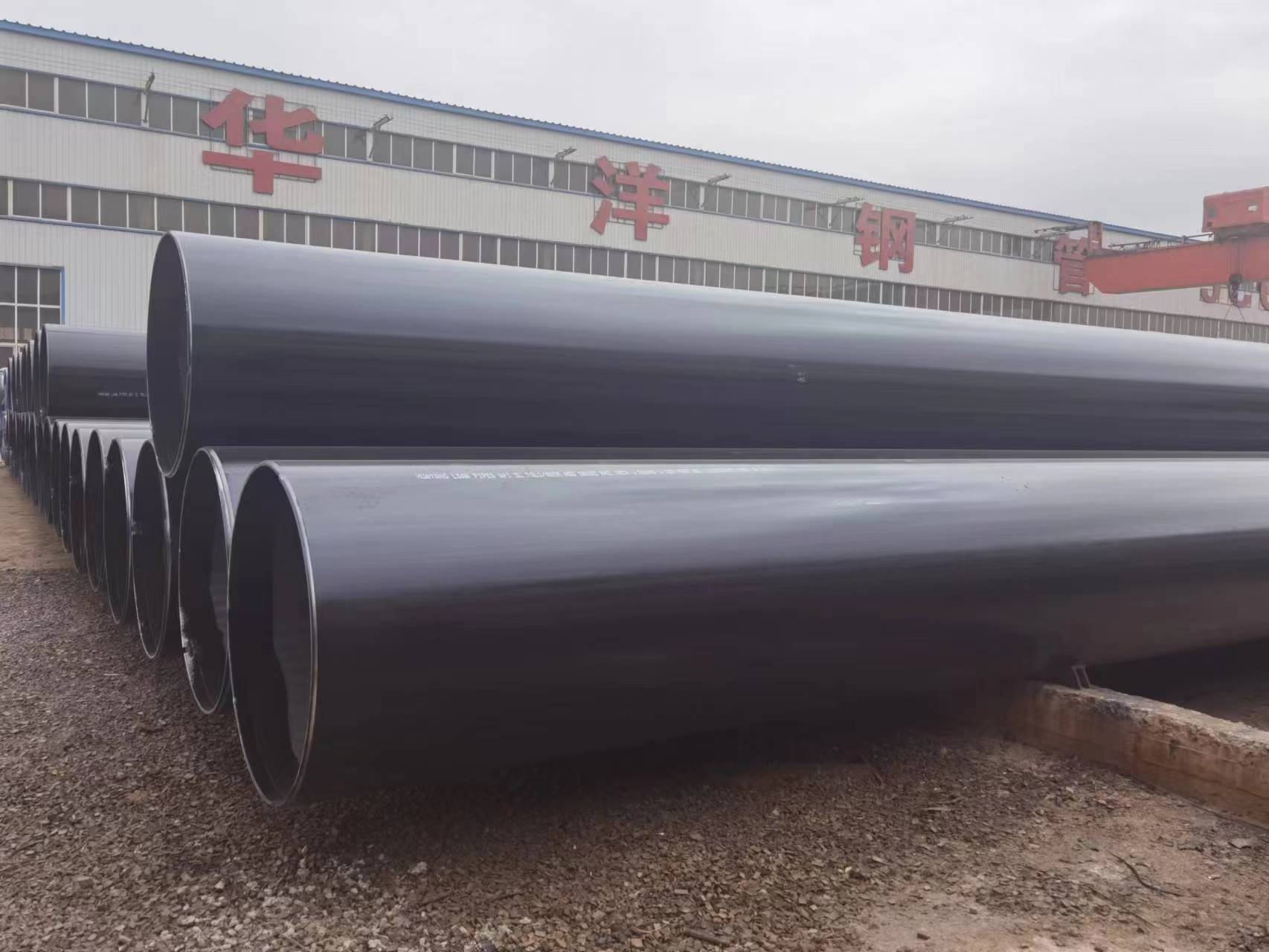

API 5L steel pipe manufacturers offer competitive pricing.

API 5L Steel Pipe Price Manufacturers An In-depth Overview

API 5L steel pipes, an essential component in the oil and gas industry, are widely used for conveying hydrocarbons due to their exceptional strength and durability. This standard, set by the American Petroleum Institute (API), ensures that these pipes meet stringent quality and performance requirements. The pricing of API 5L steel pipes is influenced by several factors, and understanding the manufacturers' perspective can be crucial for buyers in making informed decisions.

Manufacturers of API 5L steel pipes vary globally, with major players located in China, India, the United States, and Europe. These manufacturers offer a wide range of specifications, grades, and dimensions to cater to diverse project needs. The price of API 5L steel pipes is determined by factors such as raw material costs, production processes, quality control measures, and market demand.

The cost of raw materials, primarily steel, plays a significant role in determining the final price. Fluctuations in global steel prices, driven by supply and demand dynamics, geopolitical situations, or production disruptions, directly impact the manufacturing cost. Additionally, the grade of steel used - from X42 to X100 - influences the price, with higher grade pipes providing superior strength at a premium cost.

Production processes also contribute to the pricing. Welded and seamless pipes, both part of API 5L standards, have different manufacturing methods. Seamless pipes, generally more expensive due to their complex manufacturing process, offer higher pressure resistance and are preferred for critical applications Seamless pipes, generally more expensive due to their complex manufacturing process, offer higher pressure resistance and are preferred for critical applications Seamless pipes, generally more expensive due to their complex manufacturing process, offer higher pressure resistance and are preferred for critical applications Seamless pipes, generally more expensive due to their complex manufacturing process, offer higher pressure resistance and are preferred for critical applications

Seamless pipes, generally more expensive due to their complex manufacturing process, offer higher pressure resistance and are preferred for critical applications Seamless pipes, generally more expensive due to their complex manufacturing process, offer higher pressure resistance and are preferred for critical applications api 5l steel pipe price manufacturers. On the other hand, welded pipes, with a more straightforward production process, provide cost-effective solutions for less demanding projects.

Quality control measures, including non-destructive testing, hydrostatic testing, and visual inspections, add value to the product but also increase the manufacturing cost. API 5L certified manufacturers invest in advanced technology and skilled labor to ensure compliance with international standards, which may reflect in the pipe's price.

Market demand and supply conditions also play a significant role. During periods of high demand, manufacturers may hike prices, while surplus inventory could lead to competitive pricing. It is crucial for buyers to monitor market trends and engage in strategic sourcing to secure the best deals.

In conclusion, API 5L steel pipe price manufacturers consider various aspects when setting their prices, including raw material costs, production processes, quality standards, and market conditions. As a buyer, understanding these factors can help negotiate effectively and make purchasing decisions that balance quality, performance, and budgetary constraints. Always engage with reputable manufacturers who prioritize quality and adhere to industry standards to ensure long-term reliability and efficiency in your pipeline systems.

api 5l steel pipe price manufacturers. On the other hand, welded pipes, with a more straightforward production process, provide cost-effective solutions for less demanding projects.

Quality control measures, including non-destructive testing, hydrostatic testing, and visual inspections, add value to the product but also increase the manufacturing cost. API 5L certified manufacturers invest in advanced technology and skilled labor to ensure compliance with international standards, which may reflect in the pipe's price.

Market demand and supply conditions also play a significant role. During periods of high demand, manufacturers may hike prices, while surplus inventory could lead to competitive pricing. It is crucial for buyers to monitor market trends and engage in strategic sourcing to secure the best deals.

In conclusion, API 5L steel pipe price manufacturers consider various aspects when setting their prices, including raw material costs, production processes, quality standards, and market conditions. As a buyer, understanding these factors can help negotiate effectively and make purchasing decisions that balance quality, performance, and budgetary constraints. Always engage with reputable manufacturers who prioritize quality and adhere to industry standards to ensure long-term reliability and efficiency in your pipeline systems.

Seamless pipes, generally more expensive due to their complex manufacturing process, offer higher pressure resistance and are preferred for critical applications Seamless pipes, generally more expensive due to their complex manufacturing process, offer higher pressure resistance and are preferred for critical applications

Seamless pipes, generally more expensive due to their complex manufacturing process, offer higher pressure resistance and are preferred for critical applications Seamless pipes, generally more expensive due to their complex manufacturing process, offer higher pressure resistance and are preferred for critical applications api 5l steel pipe price manufacturers. On the other hand, welded pipes, with a more straightforward production process, provide cost-effective solutions for less demanding projects.

Quality control measures, including non-destructive testing, hydrostatic testing, and visual inspections, add value to the product but also increase the manufacturing cost. API 5L certified manufacturers invest in advanced technology and skilled labor to ensure compliance with international standards, which may reflect in the pipe's price.

Market demand and supply conditions also play a significant role. During periods of high demand, manufacturers may hike prices, while surplus inventory could lead to competitive pricing. It is crucial for buyers to monitor market trends and engage in strategic sourcing to secure the best deals.

In conclusion, API 5L steel pipe price manufacturers consider various aspects when setting their prices, including raw material costs, production processes, quality standards, and market conditions. As a buyer, understanding these factors can help negotiate effectively and make purchasing decisions that balance quality, performance, and budgetary constraints. Always engage with reputable manufacturers who prioritize quality and adhere to industry standards to ensure long-term reliability and efficiency in your pipeline systems.

api 5l steel pipe price manufacturers. On the other hand, welded pipes, with a more straightforward production process, provide cost-effective solutions for less demanding projects.

Quality control measures, including non-destructive testing, hydrostatic testing, and visual inspections, add value to the product but also increase the manufacturing cost. API 5L certified manufacturers invest in advanced technology and skilled labor to ensure compliance with international standards, which may reflect in the pipe's price.

Market demand and supply conditions also play a significant role. During periods of high demand, manufacturers may hike prices, while surplus inventory could lead to competitive pricing. It is crucial for buyers to monitor market trends and engage in strategic sourcing to secure the best deals.

In conclusion, API 5L steel pipe price manufacturers consider various aspects when setting their prices, including raw material costs, production processes, quality standards, and market conditions. As a buyer, understanding these factors can help negotiate effectively and make purchasing decisions that balance quality, performance, and budgetary constraints. Always engage with reputable manufacturers who prioritize quality and adhere to industry standards to ensure long-term reliability and efficiency in your pipeline systems. Latest news

-

High Quality Mild Steel Pipe Manufacturers in China for Exporting Premium Industrial Solutions

NewsAug.01,2024

-

Exploring Key Characteristics of Wholesale API Steel Pipes for Your Business Needs

NewsAug.01,2024

-

Current Wholesale Prices for ERW Steel Pipes in the Market Right Now

NewsAug.01,2024

-

Exploring the Diverse Applications and Benefits of China Round Steel Pipes in Construction and Industry

NewsAug.01,2024

-

Top Quality API 5L ERW Steel Pipe Manufacturer Offering Reliable and Durable Solutions for Your Needs

NewsAug.01,2024

-

Reliable Supplier of Premium Quality Concrete Pipes for Durable Construction Projects

NewsAug.01,2024