Steel Grade:

API 5L PSL1 & PSL2: GR.A, GR.B, X42, X46, X52, X56, X60, X65 X70

EN10219/DN10210: S235, S235JR, S235J2H, S275, S275JR, S355JRH, S355J2H

ASTM A53: GR.A, GR.B

ASTM A252: GR.1, GR.2, GR.3

ASTM A500: GR.A, GR.B, GR.C, GR.D

GB/T9711: L175, L210, L245, L290, L320, L360, L290, L320, L360, L390, L415, L450, L485, L555

GB/T3091, SY/T5037: Q195, Q215, Q235, Q275, Q295, Q345

Coating Standard:

ANSI/AWWA C104/A21.4 American National Standard for Cement-Mortar Lining for Ductile-Iron Pipe and Fittings for Water

ISO 21809: Petroleum and natural gas industries -- External coatings for buried or submerged pipelines used in pipeline transportation systems

DIN 30670: Polyethylene coatings of steel pipes and fittings

AWWA C210: Liquid-Epoxy Coatings and Linings for Steel Water Pipe and Fittings

AWWA C213: Fusion-Bonded Epoxy Coating for the Interior and Exterior of Steel Water Pipelines

Size:

Outer Diameter: 406.4mm-1422mm(16”-56”)

Wall Thickness: 9.5mm-50mm

Length: 6mtr-12.5mtr

End: Plain/square ends (straight cut, saw cut, and torch cut), or Beveled ends

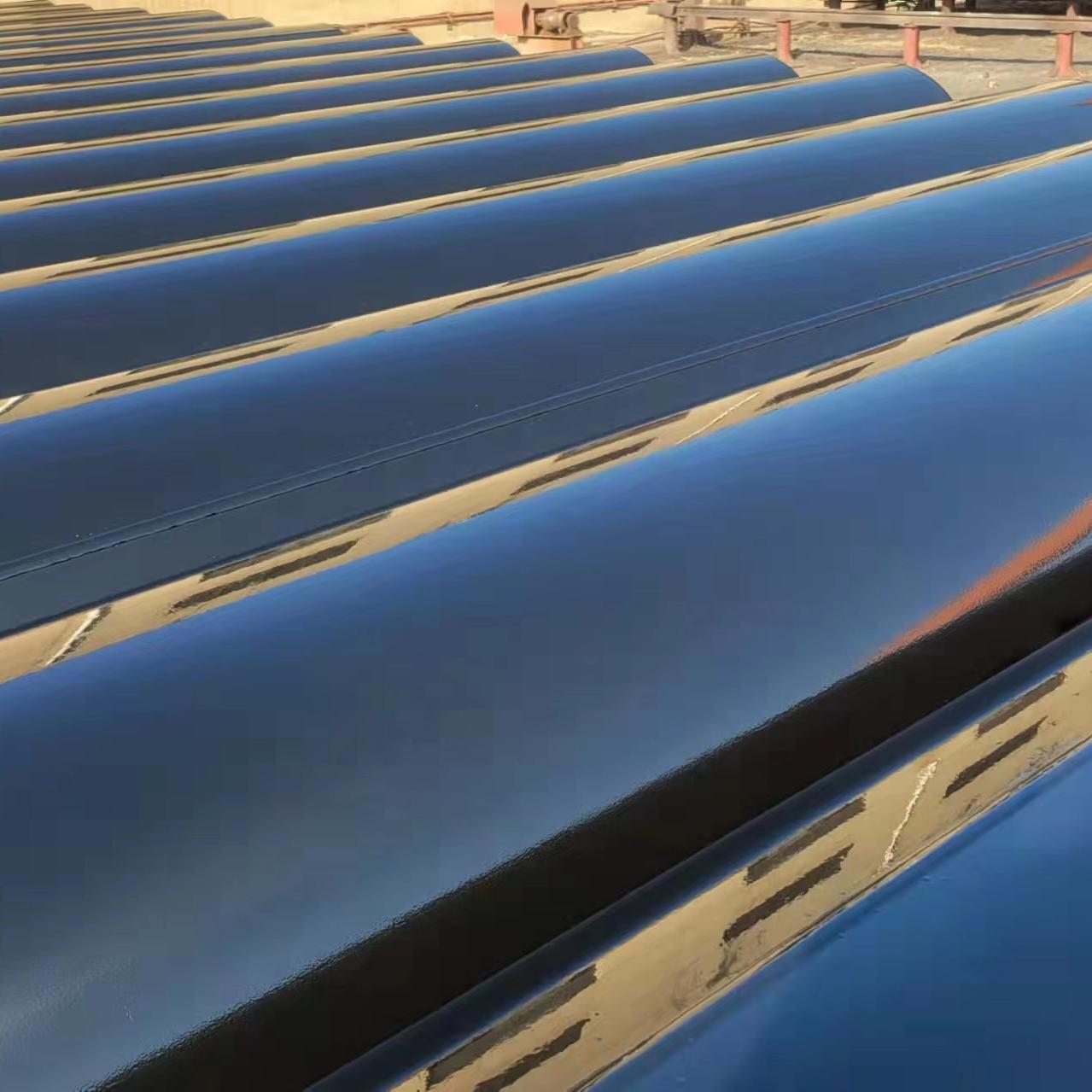

Surface: Lightly oiled, Hot dip galvanized, Black painted, Varnish coating/Anti rust oil, Protective Coatings (Epoxy, Fusion Bond Epoxy, 3-layers PE)

Supply ability: 10,000 Metric Tons/Month

Delivery time: 7 day at fastest, based on total quantity or as customers’ requirements

Loading port: Tianjin(Xingang) Port or Shanghai port

Payment Term: T/T, L/C at sight or negotiate

Our Advantage:

Huayang specialized in manufacturing welded carbon steel pipes for 14 years. The annual output is around 1500,000 tons. Our products have been exported to 40 countries and regions till now, such as Canada, Hong Kong, Vietnam, Bangladesh, The U.A.E, America, Spain, Italy, Netherlands, Kuwait, Saudi Arabia etc. So any inquiry or special demands will get fast and most professional reply.

Mechanical Properties

| Standard |

Class |

Grade |

|

Yield Strength (MPa) |

Tensile Strength (MPa) |

Elongation

(%) |

Y.S/T.S |

| API SPEC 5L /ISO 3183 |

PSL1 |

L245/GR.B |

min |

245 |

415 |

b |

- |

| L290/X42 |

min |

290 |

415 |

b |

- |

| L320/X46 |

min |

320 |

435 |

b |

- |

| L360/X52 |

min |

360 |

460 |

b |

- |

| L390/X56 |

min |

390 |

490 |

b |

- |

| L415/X60 |

min |

415 |

520 |

b |

- |

| L450/X60 |

min |

450 |

535 |

b |

- |

| L485/X70 |

min |

485 |

570 |

b |

- |

| PSL2 |

L245N/BN

L245M/BM |

min |

245 |

415 |

b |

- |

| max |

450 |

760 |

b |

0.93 |

L290N/X42N

L290M/X42M |

min |

290 |

415 |

b |

- |

| max |

495 |

760 |

b |

0.93 |

L320N/X46N

L320M/X46M |

min |

320 |

435 |

b |

- |

| max |

525 |

760 |

b |

0.93 |

L360N/X52N

L360M/X52M |

min |

360 |

460 |

b |

- |

| max |

530 |

760 |

b |

0.93 |

L390N/X56N

L390M/X56M |

min |

390 |

490 |

b |

- |

| max |

545 |

760 |

b |

0.93 |

L415N/X60N

L415M/X60M |

min |

415 |

520 |

b |

- |

| max |

565 |

760 |

b |

0.93 |

| L450M/X65M |

min |

450 |

535 |

b |

- |

| max |

600 |

760 |

b |

0.93 |

| L485M/X70M |

min |

485 |

570 |

b |

- |

| max |

635 |

760 |

b |

0.93 |

| L555M/X80M |

min |

555 |

625 |

b |

- |

| max |

705 |

825 |

b |

0.93 |